- Trainer: Dr. Saeed Roostaee

- Comment on this post or contact us for more details

- Duration: 4 days

- Type: Face to face

Parts of the course topics:

⦁ Introduction to power system

⦁ The Per-Unit System

⦁ Per Phase Analysis

⦁ Symmetrical Components

⦁ Fourier Transform signal

⦁ Faults in Electrical System

⦁ Consequences of SC Faults

⦁ Types of Electric Faults

⦁ Establishment of SC

⦁ SC Calculation IEC 60909

⦁ Typical Fault criteria

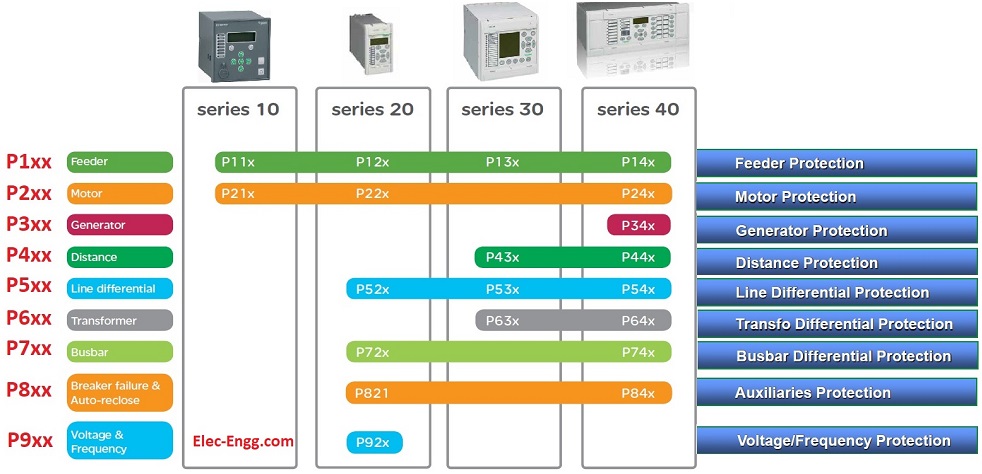

⦁ Intro Power Sys Protection

⦁ Electromechanical Relays

⦁ Numerical Relays

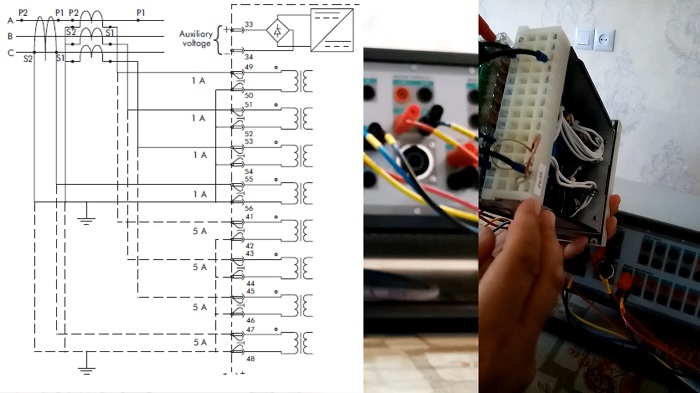

⦁ Current Transformers

⦁ Voltage Transformers

⦁ Overcurrent

⦁ DOC (ANSI 67)

⦁ Coordination

⦁ Earthing

⦁ Line-To-Ground Faults

⦁ Earth Fault 50N 51N

⦁ Sensitive Earth Fault 50Ns 67Ns

⦁ Power Transformer Faults

⦁ Winding & Terminal Failures

⦁ The Effect of Through Faults on Power Transformers

⦁ Tap Changer (OLTC) Failure

⦁ Transform Miscellaneous Failures

⦁ How do we Protect Transformers?

⦁ ABB RET 670

⦁ Differential Protection

⦁ Transformer Differential Protection

⦁ Differences between digital transformer differential relays

⦁ Simulate different cases and test the differential transformer protection function

⦁ Restricted Earth Fault Protection(REF) in Transformer

⦁ High Impedance Restricted Earth Fault Protection working principle

⦁ Stability Resistance and Metrosil Resistance in REF Protection

⦁ Low impedance REF

⦁ Transmission Lines

⦁ Line Constants

⦁ Transmission Line Faults

⦁ How do we Protect Transmission Lines?

⦁ Distance Protection for Transmission Lines

⦁ Earth-Faults and Fault Resistance

⦁ Residual Compensation Factors

⦁ Short Zone

⦁ STUB

⦁ SOTF

⦁ Power Swing

⦁ Tele-Protection and weak infeed

⦁ Fault locator

⦁ Line diff

⦁ ABB REL 670

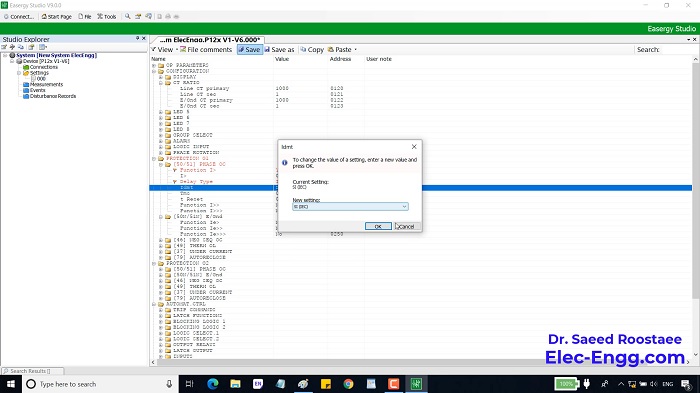

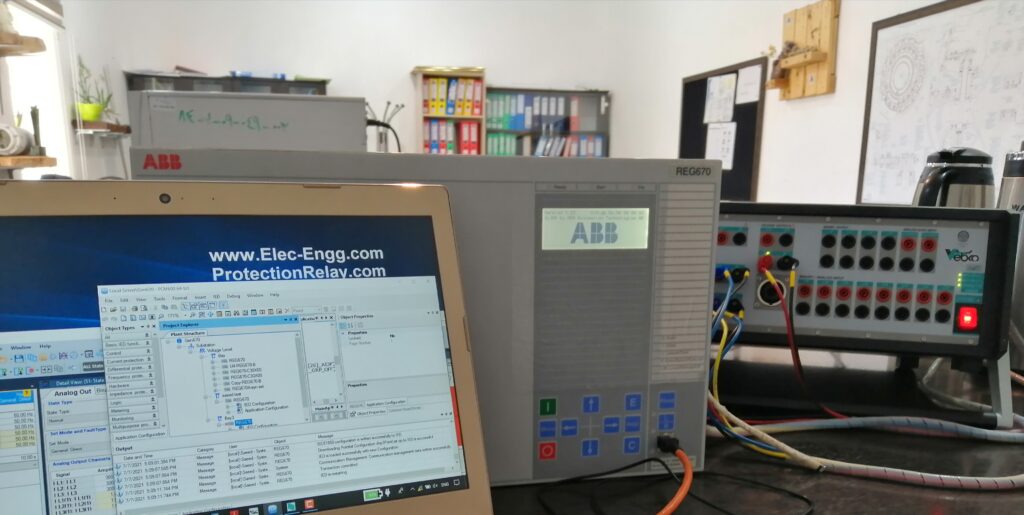

⦁ An overview of the PCM 600 functionality as well as how to get the software

⦁ Communication and Project setup, establish communication between the physical IED and PCM 600, Manage project with PCM 600, Hardware configuration

⦁ How to use the Application configuration tool in the PCM 600

⦁ How to use the Graphical Display editor tool in the PCM 600

⦁ How to use the Read and Write tool in the PCM 600

⦁ How to use the user management in the IED and PCM 600

⦁ IED online monitoring, event viewer, signal monitoring, disturbance handling

⦁ signal matrix editor tool in the PCM 600

⦁ The parameter setting tool in the PCM 600

⦁ Writing configuration into IED

⦁ IED compare

⦁ Config a simple distance protection function (SMAI, SMBI, SMBO, ZMMAPDIS, ZMMPDIS, FUFSPVC, …), configure sample signals based on the 7SA diagram

⦁ Config a simple 67N protection function, config disturbance reports (ARDAR, BRDAR, LED)

⦁ Parameter settings, XRIO format

⦁ Product guide for a pre-configured distance relay, and ordering, and modifying pre-configured distance relay based on our projects, Analog inputs (current &s for voltage), Distance Protection functions, and Communication logic

⦁ Current and Voltage protection functions and Earth Fault Protection Communication logic, Circuit Breaker Autorecloser and Tripping logics, Signal Logic and General IED functions, Virtual Binary inputs and outputs, Disturbance report analog and binary inputs

⦁ Function Block ActiveGroup

⦁ Function Block CMMXU

⦁ Function Block DRPRDRE

⦁ Function Block FXDSIGN

⦁ Function Block INTERRSIG

⦁ Function Block LEDGEN

⦁ Function Block LHMICTRL , LocalHMI

⦁ Function Block SINGLECMD

⦁ Function Block SMBI

⦁ Function Block SMBO

⦁ Function Block TESTMODE

⦁ Function Block TIMEERR

⦁ Function Block TIMER

⦁ ABB RET 670 Transformer Protection Application Template

⦁ ABB RET 670 Configuration and T2WPDIF Function block

⦁ ABB RET 670 Parameters and T2WPDIF parameters

⦁ Simulation of the differential protection algorithm in the ABB RET 670 relays

⦁ Omicron Test Universe Start page

⦁ Omicron Test Universe General settings

⦁ Omicron Test Universe Phasor view, Impedance view

⦁ Omicron CMC Hardware connection

⦁ Omicron Test Universe Test object, Overcurrent RIO block, testing of overcurrent

⦁ Omicron Test Universe Settings of the Overcurrent test module

⦁ Omicron Test Universe Diff parameters

⦁ Omicron Test Universe Diff RIO block

⦁ Omicron Test Universe Diff configuration

⦁ Omicron Test Universe Diff Operating Characteristic

⦁ Omicron Test Universe Diff Trip Time Characteristic & Diff Harmonic Restraint

⦁ RIO and XRIO history and why we should use this format for relay testing, RIO structure, XRIO structure, Differences between RIO and XRIO files, XRIO features & benefits, LinkToXRIO

⦁ XRIO template, How to Import Relay Settings, How to find a proper XRIO template and filter based on the relay

⦁ Common problems while loading the relay settings into a template and how to solve the issues, XRIO template based on the relay versions

⦁ Explain a case study XRIO file

⦁ Modify a case study XRIO file

⦁ Modify the XRIO template, RIO blocks

⦁ Distance RIO block

⦁ Advance Distance Test Module settings

⦁ Distance protection function principal, Impedance View

⦁ Analysis of several faults visually in the impedance view

⦁ Analysis of several distance relays (RAZOA, ABB REL670, SEL421, Siemens 7SA8x, MiCOM P442, NR PCS 931S, Protecta)

⦁ Distance Test Module settings

⦁ Preparing XRIO file for testing of impedance protection functions