- Type: Online-Training

- Trainer: Dr. Saeed Roostaee (Profile)

- Language: En

- Duration: 3 days

- Dates and Registration: End of this post

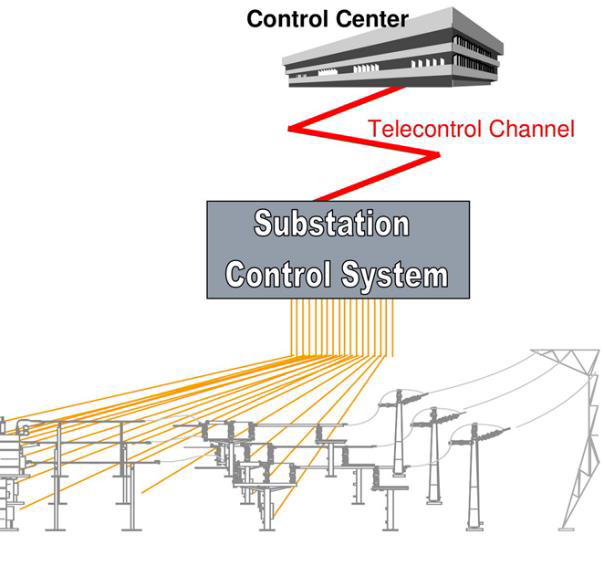

SAS introduction:

- Substation Automation Structure

- Conventional Control & Protection

- Modern Substation Automation (SA)

- Implementation of Intelligent Technology

- Intelligent SA Architecture

- Digital Substation

- Monitoring via IEDs for Protection

- Block diagram for a typical numerical relay

- Analogue to digital conversion

- Digital Phasor Measurement

Communication Introduction

- Parallel interface example

- Serial interface example

- Communication Medium

- Frame

- Baud rate

- Baud rate effect on frames

- Medium Access Methods

- Industrial Communication Protocols

- Profi-bus

- Profi-net

- RS232

- SPI

- Ethernet

- Parity & CRC

- Basic Data Types in Power System

- Info Identification for IEC 60870-5-103

OSI model

- Physical Layer

- Data link Layer

- Network Layer

- Application Layer

- Ethernet Addressing

- Frame and Packet

- TCP and UDP

- TCP/IP & its application in SAS

- UDP/IP & its application in SAS

IEC 60870

- What is IEC 60870-5?

- Introduction in IEC 60870-5 protocol-101/104 protocol

- Standard Protocols based on IEC 60870-5

- IEC 60870-5-101 features

- IEC 101 Telegram structure

- Cause of transmission

- ASDU (Application Service Data Unit)

- ASDU type identification

- Quality description

- IEC 60870-5-101 physical layer

- IEC 60870-5-101 Data Link layer

- IEC 60870-5-101 Application layer

- IEC 60870-5-104 stack layer

- Installation guidelines and configuring aids

- Network examples and network configuring

- IEC 60870-5 Configuration in DIGSI 5

- configuration of an IEC connection

- time synchronization in IEC 60870-5 protocol

IEC 60870-104 simulation

- IEC104 slave device

- IEC 60870 – 5 – 104 Signals Type

- COMMAND – IEC 60870-5-101

- Command IEC 60870 – 5 – 104

- Master IEC 60870 – 5 – 104 Protocol Test

- Timeout

- DEVICE IEC 60870 – 5 – 104 SLAVE PROPERTIES

IEC 60870-104 config in SIPROTEC 5

- SIPROTEC 5 Hardware

- General Settings

- User interface

- SIPROTEC 5 Config Procedure

- IEC 60870-104 config

- IEC 60870-104 simulation

Dates and Registration

| Date | Status |

| 22-24 March 2024 | Full (no seats available) |

| 6-8 May 2024 | Open (EUR 1100) |

| 18-20 June 2024 | Full (no seats available) |

| 16-18 Aug 2024 | Open (EUR 1400) |

| 14-16 Nov 2024 | Open (EUR 1400) |

IEC 60870-5 is an international standard that defines communication protocols and data exchange formats for telecontrol systems used in the monitoring and control of industrial processes and power systems. Specifically, IEC 60870-5 specifies the protocols for interfacing remote terminal units (RTUs) and control centers in supervisory control and data acquisition (SCADA) systems. The standard outlines communication profiles for telecontrol equipment, detailing formats for information exchange, data frames, and error handling mechanisms to facilitate reliable and efficient communication between devices in industrial automation and power system applications. Adherence to the IEC 60870-5 standard helps ensure compatibility, interoperability, and seamless integration of equipment from various suppliers in SCADA systems, contributing to operational reliability and efficiency.

features:

IEC 60870-5-101 is a specific part of the IEC 60870-5 standard that defines a balanced communication protocol for the telecontrol of electrical substations. Some features of IEC 60870-5-101 include a master/slave communication model, support for serial interfaces (such as RS-232 or RS-485), structured data frame formats for transmitting control commands and telemetry data, error checking mechanisms for data integrity, and application profiles tailored for the telecontrol of electricity substations. This protocol is widely used in SCADA systems for monitoring and controlling substations, providing a reliable and standardized communication method for efficient operation and maintenance of power distribution networks.

In IEC 60870, the ASDU (Application Service Data Unit) is a fundamental concept used to structure and exchange information between devices in SCADA systems. The ASDU serves as a standardized format for encapsulating control commands, measurements, status information, and other data relevant to supervisory control and monitoring. It is designed to ensure interoperability and consistency in communication between remote terminal units (RTUs) and control centers, allowing for efficient data exchange and reliable operation in industrial automation and power system applications. By defining the structure and content of the ASDU, IEC 60870 provides a common framework for transmitting and interpreting data within the telecontrol systems, enhancing system performance and reliability.

The physical layer of IEC 60870-5-101 standard specifies the requirements for the physical connection and communication characteristics between devices in a telecontrol system. It defines parameters such as voltage levels, signaling rates, modulation techniques, and electrical interfaces to ensure reliable data transmission over serial communication links like RS-232 or RS-485. By standardizing the physical layer, IEC 60870-5-101 facilitates interoperability and compatibility between different devices and systems, enabling efficient and secure telecontrol communication within power grids and other industrial environments.

In DIGSI 5, the configuration of IEC 60870-5 protocols involves defining the communication parameters, addressing, and mapping of data objects between devices in a telecontrol system. Users can set up communication links, configure station addresses, define data types and structure, and map data points between remote terminal units (RTUs) and control centers using the IEC 60870-5 standard. DIGSI 5 offers a user-friendly interface with tools for configuring the IEC 60870-5 protocols, enabling users to create reliable and efficient telecontrol systems compliant with the standard. Through the configuration process in DIGSI 5, users can establish seamless communication and data exchange between different elements of the telecontrol system, facilitating automation and monitoring functionalities in various industries.

Time synchronization is a critical aspect of the IEC 60870-5 protocol, especially in systems where precise timing is essential for coordinating control actions and data exchange between devices. The protocol includes provisions for time synchronization through mechanisms like the Time-of-Day (ToD) information exchange between master and slave devices, ensuring that all elements in the system are operating on a synchronized clock. By maintaining accurate time synchronization, IEC 60870-5 protocol helps to improve the reliability, efficiency, and coordination of telecontrol systems, which are vital for applications in power system automation, industrial processes, and other sectors where time-critical operations are involved.

Simulating IEC 60870-104 protocols is important for testing and validating telecontrol systems before deployment. Using simulation tools, users can emulate the behavior of IEC 60870-104 devices, simulate different scenarios, and assess the system’s performance under various conditions. This allows for thorough testing of communication links, data exchange, and error handling mechanisms, ensuring that the telecontrol system functions as intended and meets operational requirements. By conducting simulations with IEC 60870-104 protocol, users can identify potential issues, optimize system configurations, and enhance the reliability and efficiency of telecontrol systems in critical infrastructure applications.