Learning is a continuous process and enables us to be competitive in our field.

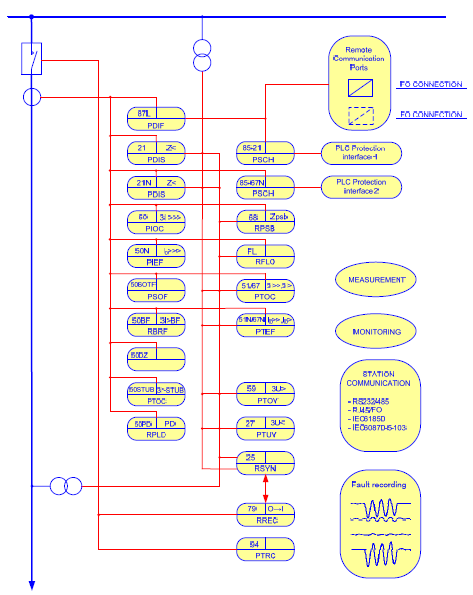

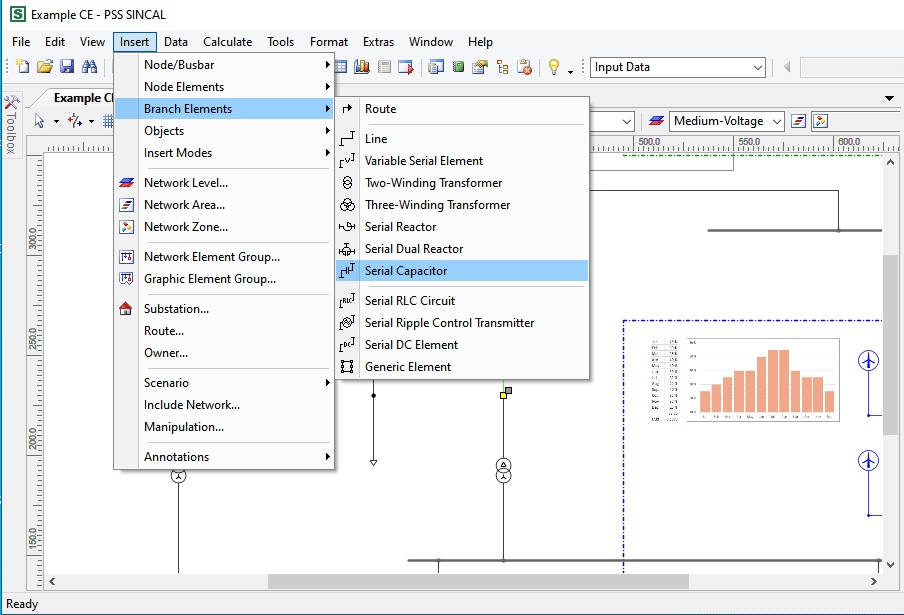

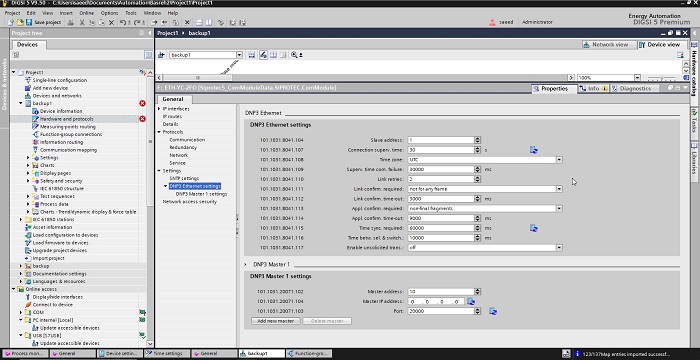

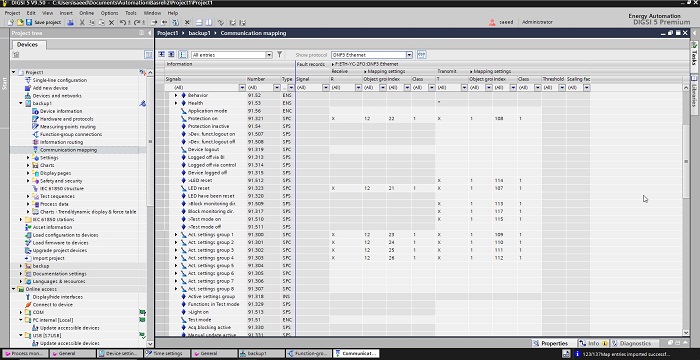

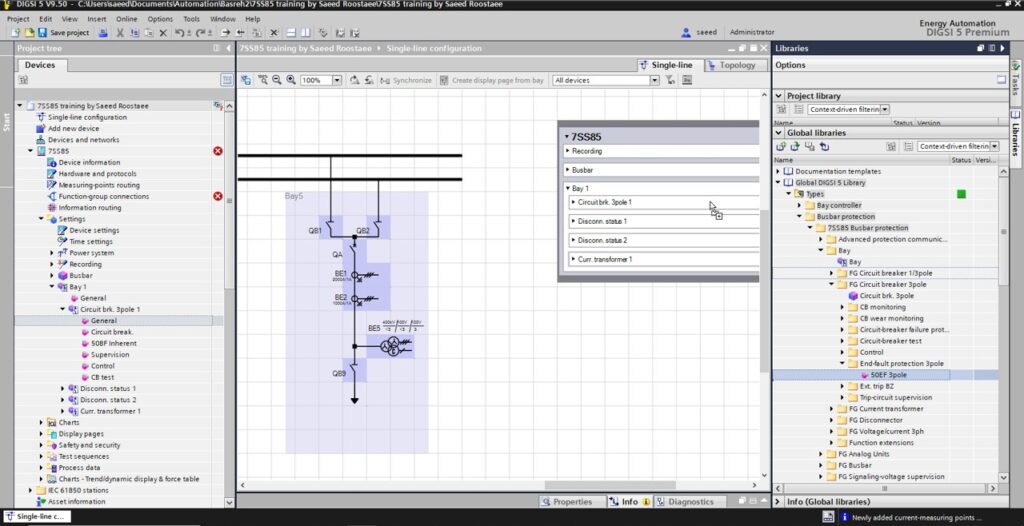

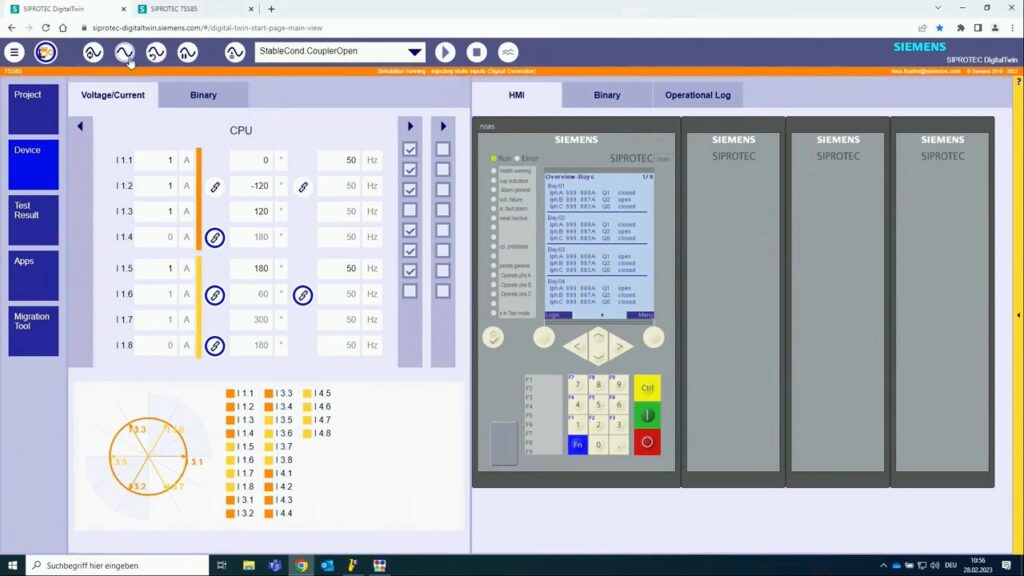

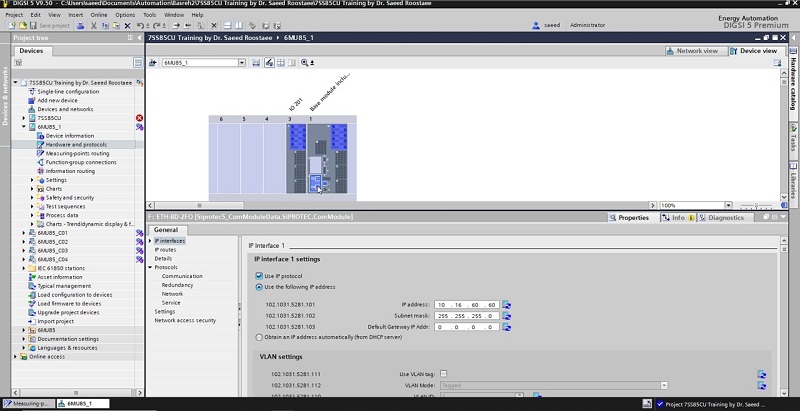

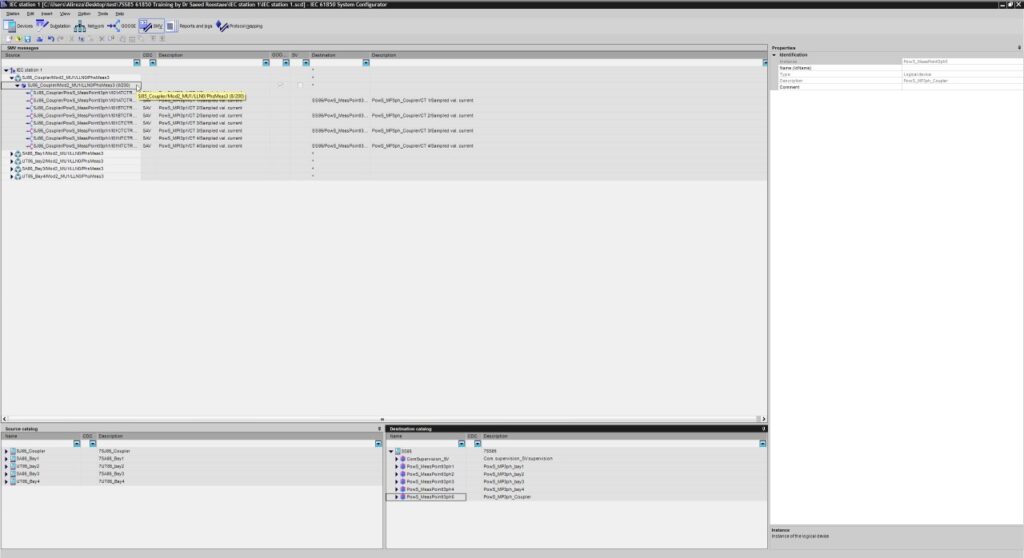

In this package, you get Trained DIGSI 4 and DIGSI 5 to work with SIPROTEC 4 & 5, how to work with Etap software, and how to use IEC 61850 for integration and communication between different equipment brands.

Product detail:

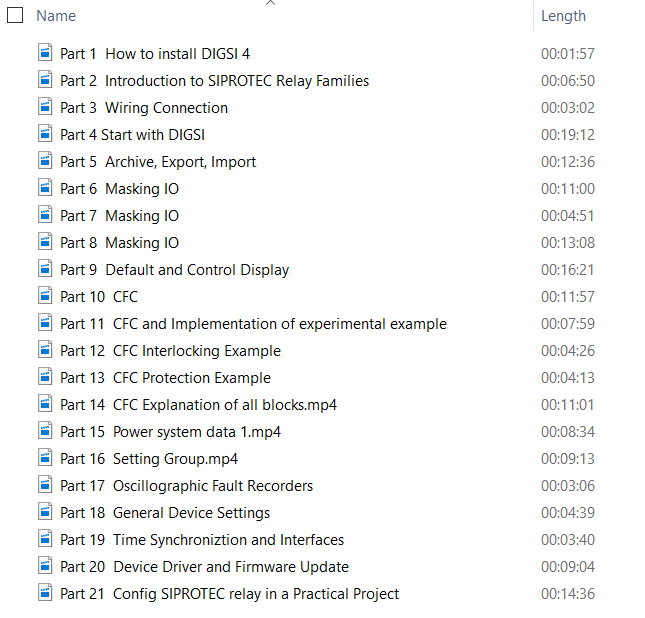

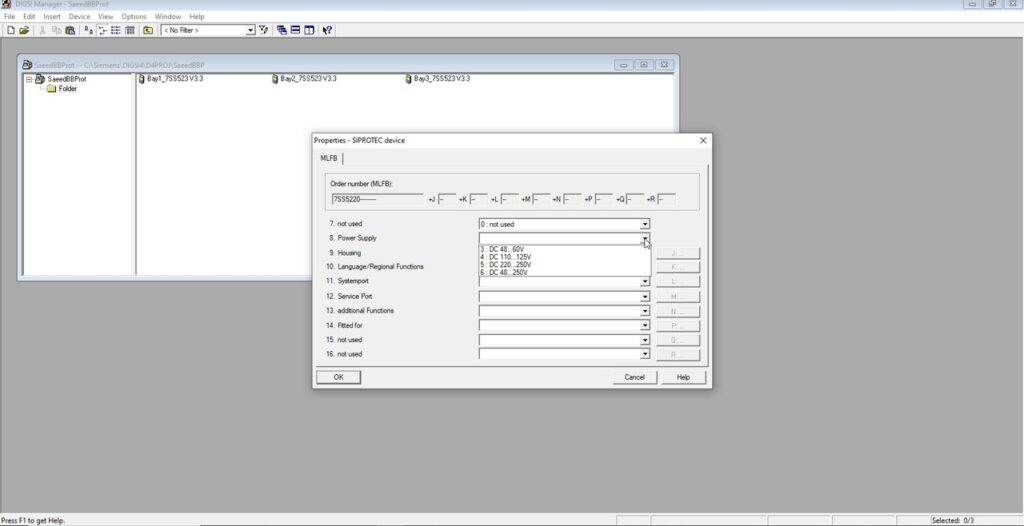

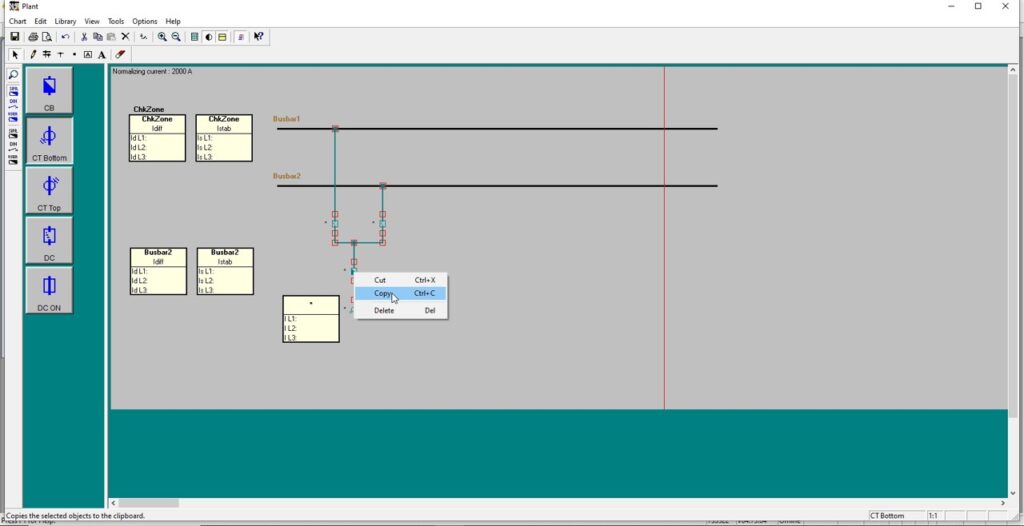

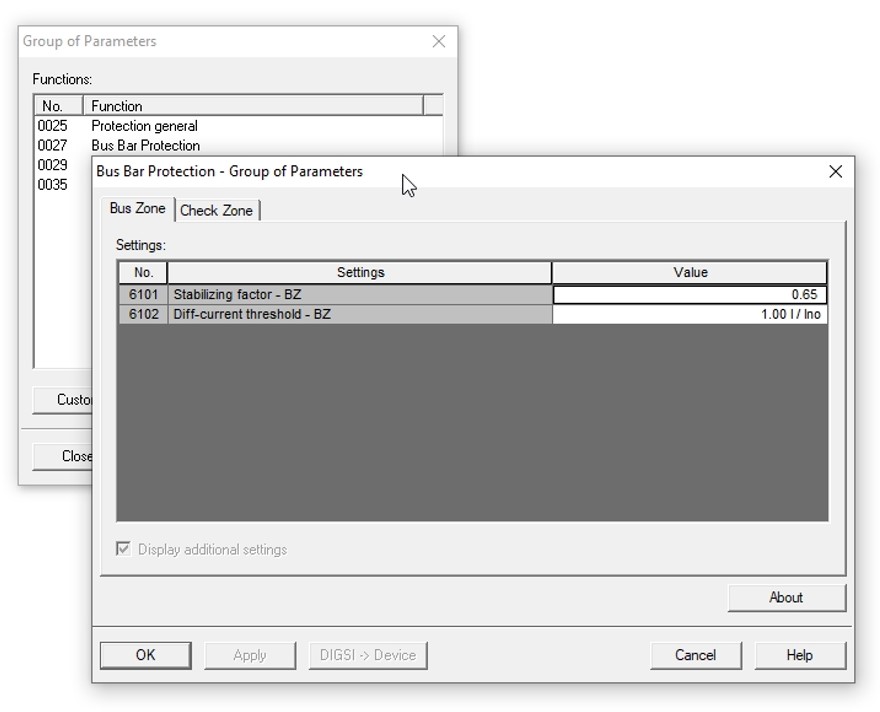

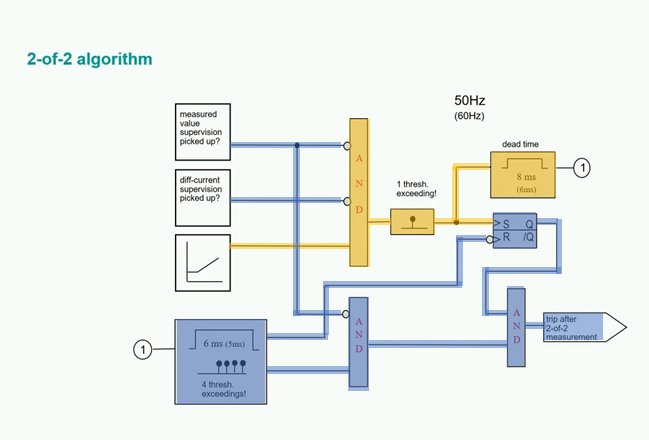

- DIGSI 4 video training (3 hrs)

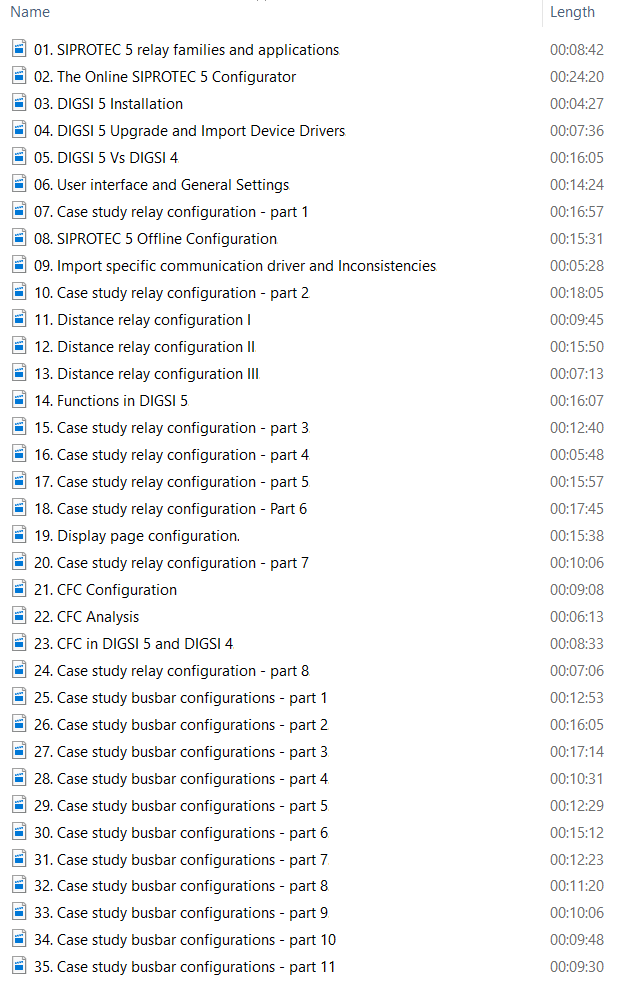

- DIGSI 5 video training (7 hrs)

- IEC 61850 training (4 hrs)

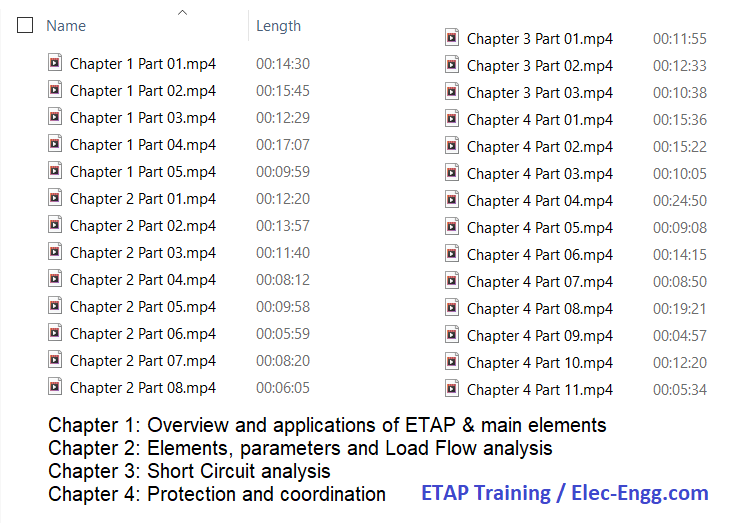

- ETAP for protection engineers (5.5 hrs)

- Trainer: Dr. Saeed Roostaee

- Language: English

- Full lifetime access

- DIGSI 5 Training: 435 Minutes – Full HD Size ( 1.9 GB), In English, By Dr. Saeed Roostaee

- DIGSI 4 Video Training: 185 Minutes, In English, By Dr. Saeed Roostaee

- IEC 61850 configuration Video Training: 4 hrs Language, In English, By Dr. Saeed Roostaee

- ETAP Video Training: 5.5 hrs, In English

contact us to get this impressive IEC61850 collection

- IEC 61850 Precision Time Protocol IEEE 1588

- IEC 61850 PRP Redundancy

- IEC 61850 Quality of Service

- IEC 61850 Redundancy Protocols

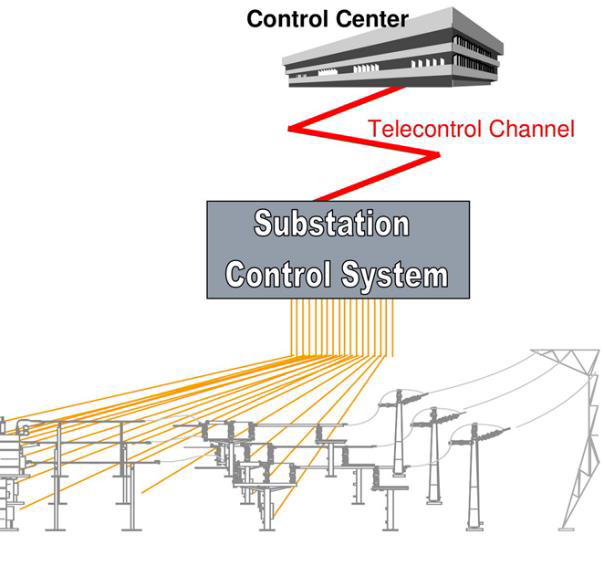

- IEC 61850 Substation Architecture

- IEC 61850 Substation Design Considerations

- IEC 61850 Time Synchronization

- IEEE 1588 – Master, Slave, and Transparent Clocks

- IEEE 1588 Synchronization Basics

- Important Properties of PTP

- Integrating Serial and IP Ethernet

- Introduction to IEEE 1588 Precision Time Protocol

- Network Management System Deployment Scenarios

- Network Management System Security

- Network Security- The Defense in Depth Model

- NMS User Guide- Device Discovery

- NMS User Guide- Permissions and Users

- NMS User Guide- Statistics

- NMS User Guide- Views and Alarms

- Product Overview – RAPTOREye

- PTP Profiles

- PTP Timing Requirements in Power Systems

- Securing a Switch and Functional Architecture

- Security Standards and the NERC CIP Framework

- Serial IP Conversion Use Case

- Switch Hardening_ Local Password and Access Authentication

- Switch Hardening- Finalizing the Security Configuration

- Switch Hardening- Secure Management and Configuration

- The Best Master Clock Algorithm

- The Gap Between Legacy Serial and Ethernet

- The Network Management System FCAPS Model

- Time Transfer Technology Comparison

- Virtual Serial Port Redirection

- What is a Network Management System (NMS)

- Name Size Date Modified

- Best Practice – Securing SNMP

- Best Practice_ Securing Management Protocols

- Best Practice- Enabling Remote Logging

- Best Practice- Time Sync, Disable Services, and Port Security

- Converting Serial to IP

- Core Redundancy and OSPF

- Defense in Depth Model

- Device Hardening- Best Practice Basics

- Device Level Security and Switch Functional Architecture

- Digital Substations- An Introduction to IEC 61850

- Ethernet Network Overview

- Gateway Redundancy – VRRP

- How does a VLAN work

- How PTP IEEE 1588 v2 Works

- HSR-PRP Redundancy

- IEC 61850 Communication Protocols

- IEC 61850 HSR Redundancy

- Interior Routing Protocol

- Layer 2 and Redundancy

- Layer 3 Concepts – Routing

- MAC and IP Addressing Format

- Managed vs Unmanaged Switch and Router

- Migration from Serial to Ethernet

- Redundancy Architecture from Substation to Control Center

- Redundant Network Timing Requirements

- Routing Functions and The Routing Table

- Static Routing vs. Dynamic Routing

- STP and RSTP Redundancy

- The Physical Layer

- VLAN Basics

- VLANs (IEEE 802.1Q)

- VLANs and Redundancy

- VLANs, Routing, and Cybersecurity

- What Is a Switch

- What is a VLAN

- What is Ethernet

- Bridging the Gap Ethernet, Serial, and Legacy Equipment in Substations

- Digital Substation Communications – What you Need to Know About IEC61850 Network Design

- Educational Training Introduction_ Networking 101 For OT Professionals

- IEC61850 Overview Video

- It’s about Time – Intro to IEEE 1588 and Precision Time Protocol

- Keeping an Eye Out_ Understanding Network Management Utilization

- Network Hardening, NERC CIP and the Smart Grid

- Network Redundancy- What Are Your Options- Why Choose One Technology over Another

- Networking 101 for OT Professionals_ Ethernet and its Application in Critical Utility Networks

- Networking 101 For OT Professionals- Making Sense of the Layers. Benefits of Layer 2 and Layer 3

- Switch Hardening Best Practices- How to Secure Your Industrial Network

- VLAN Fundamentals and Its Benefit in Network Design for Mission Critical Applications

- Name Size Date Modified

- Alex Apostolov about the past, present and the future of relay protection

- Christoph Brunner about origins of IEC 61850 and its future developments — Big Energy.

- IoT for Utility and Industrial Power Grids- Where Is the value-

- Route to IEC 61850 (2016)- The Concept of IEC 61850

- Route to IEC 61850- Engineering IEC 61850 systems

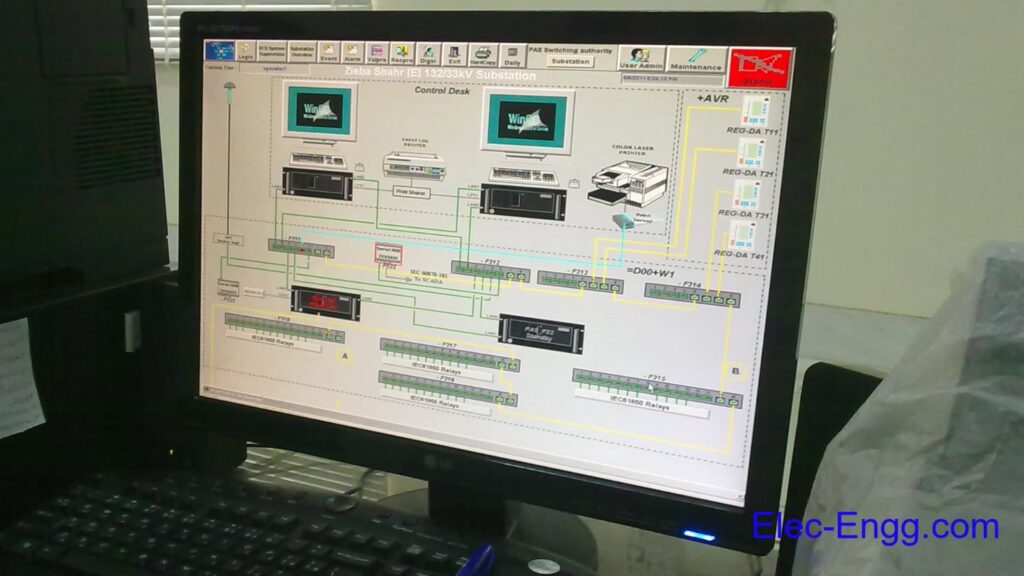

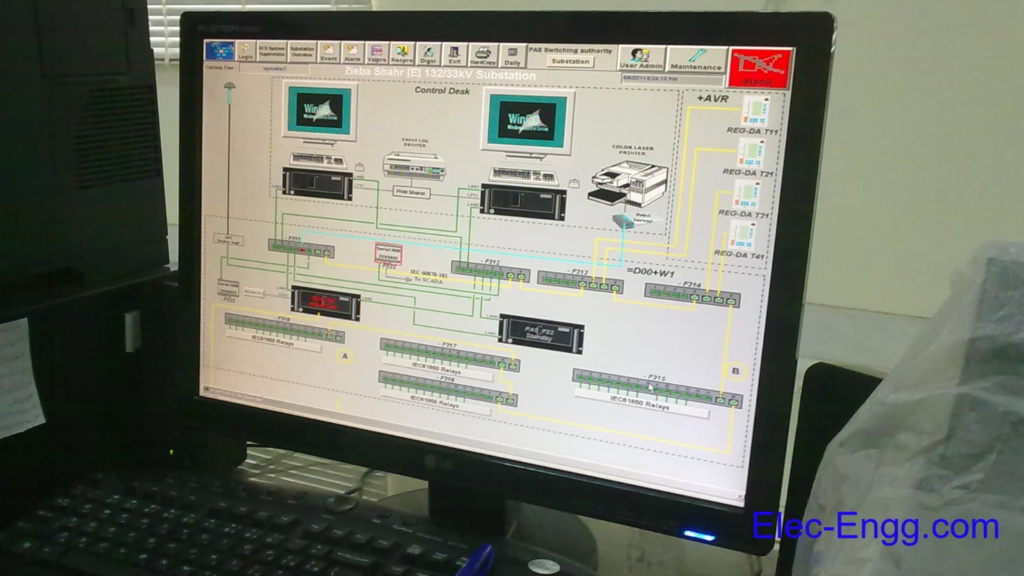

- Route to IEC 61850- HMI and Station Control

- Route to IEC 61850- Testing IEC 61850 Systems

- Route to IEC 61850- The Concept of IEC 61850

- Route to IEC 61850- Time Synchronization for IEC 61850

- The Future of Industrial Automation Video – GE Intelligent Platforms

- Welcome to the Digital Substation World I Episode 01

- ABB Goose config

- Cara Create ICD_SCD File (IEC61850 Protocol) dari Relay Reyrolle Argus 7SR

- Fiber Optic and Data Transferring between Substations and OTDR

- GE course

- GE DCS

- GE Geese confgi procedure

- Hands on Protection Testing using IEC 61850

- How to configure IEC 61850 with Easergy Studio

- How to enable Virtual Machine on Latest Windows Host Operating System

- How to generate the IEC 61850 MMS GOOSE Protocol traffic using SCL files with IEDScout

- How to perform the compare and find difference between the SCL files

- How to save the SCL file from IEDScout

- How to setup OpenSCD to be used in offline

- How to subscribe the GOOSE messages from third-party relays to ABB make relays in PCM600

- How to use IEDScout in offline and the benefits behind

- How to use IEDScout in offline to practic

- IEC 61850 implementation-related documentation for IEDs and Tools

- IEC 61850 Overview Part 9 SCL Files

- IEC 61850 programming training

- iec61850.

- ied scout

- Introduction and contents overview

- Introduction to packet sniffing and basics of communication protocols

- Making right connections to start sniffing in switched environment

- Start capturing with Wireshark and manage its basic settings

- Using Filters

- Working with packets

- Working with capture files

- Digital substation traffic capture analysis

- Practical demonstration

- IEDScout on MBX1 IEC 61850 IED Simulation with Positive use cases

- ieee1588

- OMICRON Customer Portal Overview

- Route to IEC 61850 (2016)- The Concept of IEC 61850

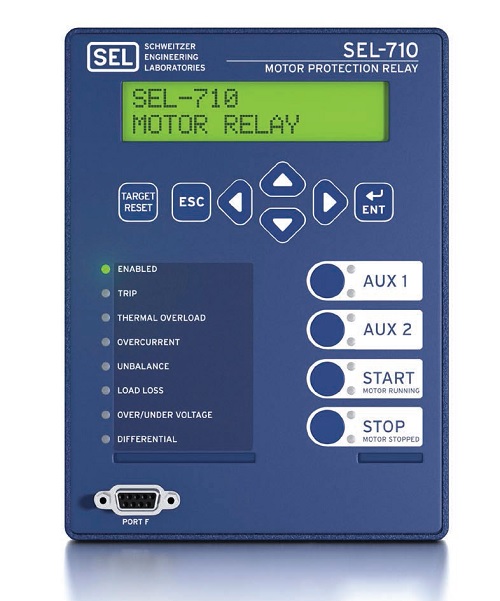

- SEL Goose config

- SETR850 schnider

- Simulating an IED from IEDScout PC with 102 port-occupied services

- StationScout offline benefits-Part-1

- STRATON IEC61850

- Trick Rahasia Edit CID File IEC61850 untuk Integrasi SIPROTEC5 PACIS Alstom

- Using IEC 61850 to Solve Protective Relaying Challenges (2011).mp4 292 M

- ABB webinar

- Awareness of IEC 61850 communication standard – Preface and tutors introduction

- digsi 4 iec61850 config

- digsi4 report

- easergy pro

- ethernet

- How does Modbus Communication Protocol Work

- IEC 61850 Data Modeling Part 2 – Triangle MicroWorks Inc

- IEC 61850 in the Modern Substation

- IEC 61850 Standard for T&D Grids

- iec 61850 webinar omicron

- IEC 61850

- IEC_61850_Simply_usable_mit_closing.

- iot – 38 – Lecture 3.3 Packet Capture Demo

- Mensajes GOOSE en IEC61850 de Siemens

- omicron goose

- omicron products

- omicron SV

- Relational Database Concepts

- sip5 iec61850

- triangle

- Practical IEC 61850 for Substation Automation for Engineers and Technicians

- Video Session 2- Practical IEC 61850 for Substation Automation for Engineers and Technicians

- Video Session 3- Practical IEC 61850 for Substation Automation for Engine

- What is OSI Model

- What is the IEC 61850 protocol- How does it work- What’s the difference with other protocols

- SIPROTEC 5 certificate automation – using Enrollment over Secure Transport protocol

- Webinar SIPROTEC 5 certificate Secure Transport EST protocol

- Expert Talk – Overview of SICAM A8000, SIAPP & Web HMI

- Global Summit 2022 Digital switchgears for intelligent secondary distribution grid automation

- Global Summit 2022 Behind the scenes– Self optimized grid to the largest onshore fish farm in Norway

- Global Summit 2022 Conference Digital switchgear solutions for primary distribution

- Global Summit 2022 Conference Precisely tailored substation automation with SICAM A8000

- Global Summit 2022 Keynote Innovative technologies in electrification & automation for our future

- Global Summit 2022 Mastering distribution grid diversification by IoT SIPROTEC5

- Global Summit 2022 SICAM A8000 beyond the typical substation automation–New apps for the Etransition

- Global Summit 2022 Training How to write your own application for SICAM A8000 with SIAPP

- Migration of SICAM TOOLBOX II configuration

- SICAM Earth Fault Indicator – SICAM EFI Introduction Animation (FR)

- SICAM Earth Fault Indicator – SICAM EFI Introduction Animation

- Automation and remote terminal units SICAM A8000 RTU SIPROTEC-5 SIEMENS

- Sicam Application CP8050 Automation and remote terminal units A8000 RTU SIPROTE

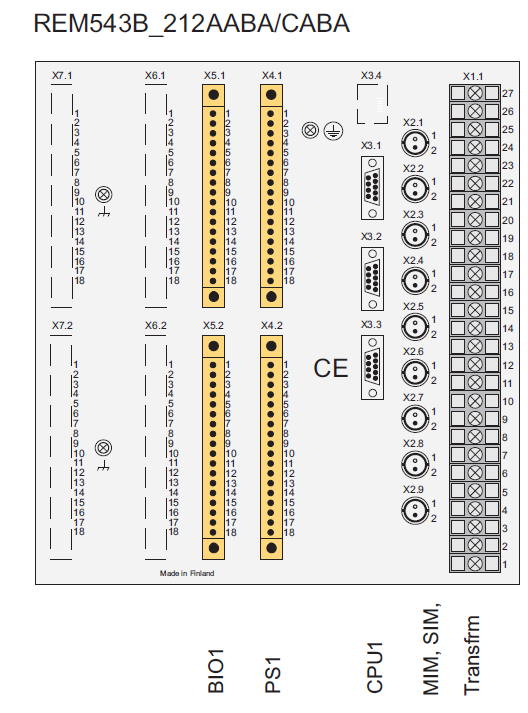

ABB CAP 505 (Computer Aided Programming system) can be used to config the ABB RED 500 and SPACOM series. This training course introduces the hardware structure of the RE 500 series and then the configuration procedure of these relays in CAP 505.

Pre-recorded Videos

- Part 01: RE 500 relay hardware explanation (26 minutes)

- Part 02: CAP 505 user interface, create a project, and add relay REF 54 (13 minutes)

- Part 03: Create project structure (16 minutes)

- Part 04: Function blocks and IO configuration (8 minutes)

- Part 05: Blocking signal by inrush and Fuse failure (9 minutes)

- Part 06: Config Trip signals (4 minutes).

- part 07: Measurements and LEDs configuration (5 minutes).

- Part 08: Disturbance recorder configuration (3 minutes).

- Part 09: LCD configuration (8 minutes).

- Part 10: settings and download to the relay (15 minutes).

Course Contents:

- The hardware structure of ABB RE 500 series (REM543, REF543, REM545, REF 541, REF543, …)

- Introduce the CAP 505 and the user interface (Caption bar, Toolbar, Project Structure, Status bar, Status bar, Menu bar)

- Create a new project and add a case study relay (manage the project, project structurization, add new Rlay REF 543, The configuration dialog for REF54x device, add communication port)

- Create project structure (define the library, add Logical POUs, Physical hardware config, resources, tasks, assign tasks, …)

- Add function block and config Inputs and outputs ( add directional Overcurretn and Direction earthfall functions, Config analog inputs, binary inputs, and binary outputs, …)

- LED, LCD, measurement, and disturbance configuration (Config trip signals to the LEDs, config measurements to the LCD, Config the breaker position to the LCD)

- Settings and upload/download (explain the main parameters of the Directional overcurrent, Direcinal earth fault, disturbance recorder, Fuse fail, inrush current, …)

How to access the training course

Buy now and start learning:

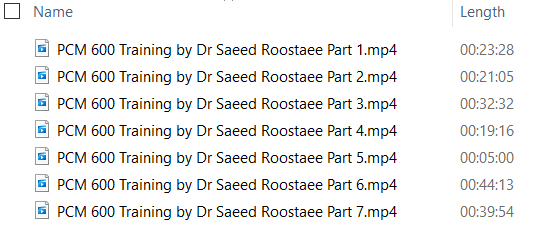

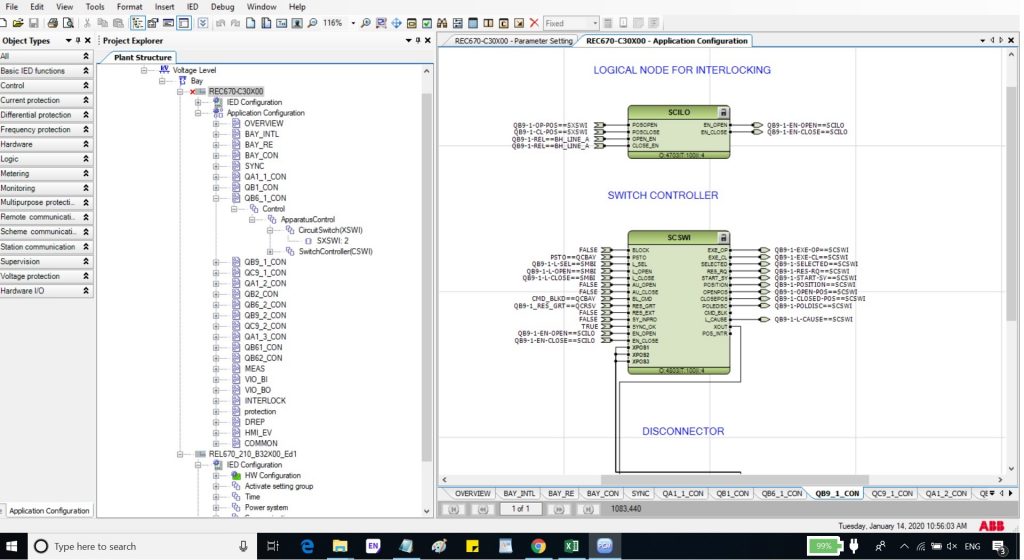

- PCM 600 Introduction

- Communication and project setup in PCM 600

- Update Manager tool

- Hardware Configuration tool

- Read from IED

- Write to IED

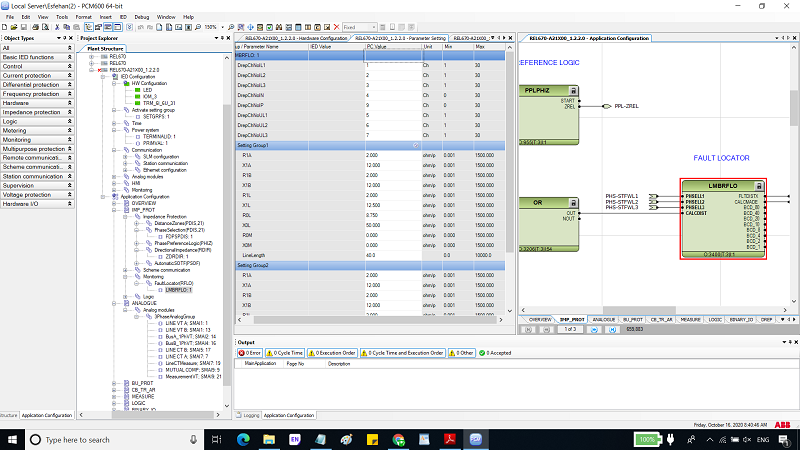

- Application configuration in PCM 600

- Signal Matrix tool

- Parameter Setting tool

- Signal matrix and parameter setting in PCM 600

- Interlinking between Signal Matrix tool and Application configuration tool

- IED Compare tool

- Disturbance Handlin tool

- Signal Monitoring tool

- PCM 600 Monitoring

- Graphical Display Editor in PCM 600

- Graphical display editor

- Migrate configuration tool

- PCM Options

- IED user Management tool

- Scheduler

- Set Technical Key tool

- Goose Communication engineering (GCB)

- Changing the SCL version of IED

- Client-Server engineering (RCB) for vertical communication

Prerequisite Training packages

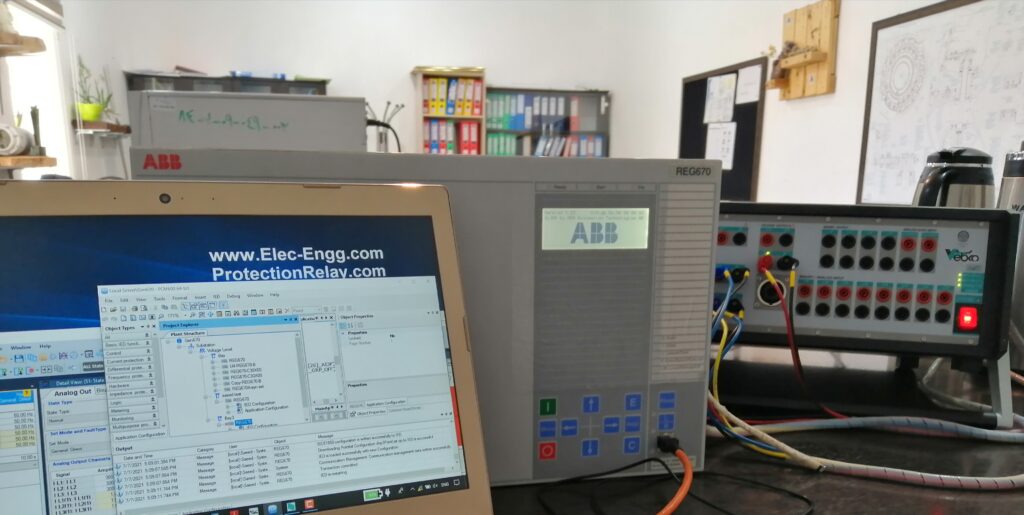

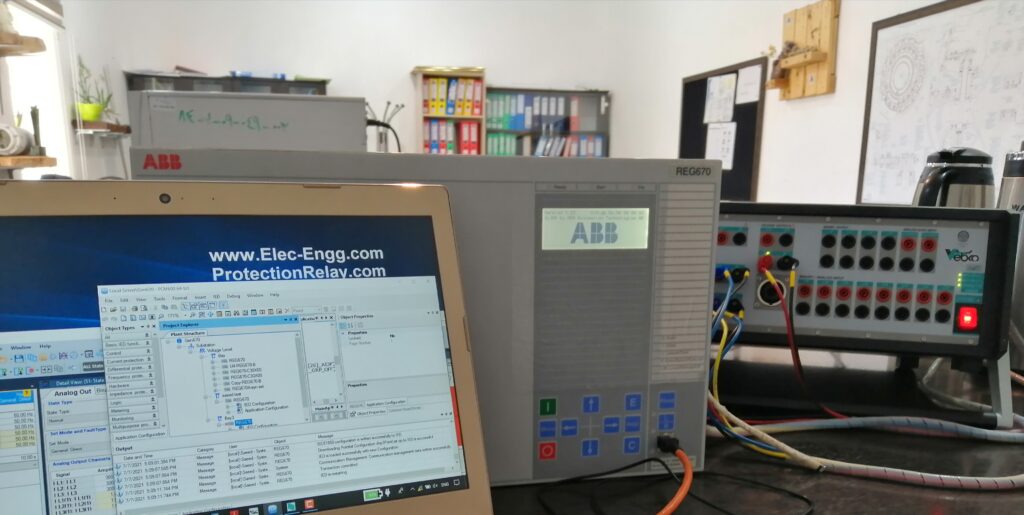

ABB REG670 Training package (Advanced level)

- Trainer: Dr. Saeed Roostaee (Profile on Linkedin)

- Pre-recorded videos

- Supplementary Files

- The course is still being recorded and new sessions will be added over time

- The course is licensed and you need a Windows computer to view the videos

- Download this course: contact us or leave a comment on this post

- For more info, please leave a comment on this post or contact us on WhatsApp: +989129613659

Course Details:

Configuration in the PCM600

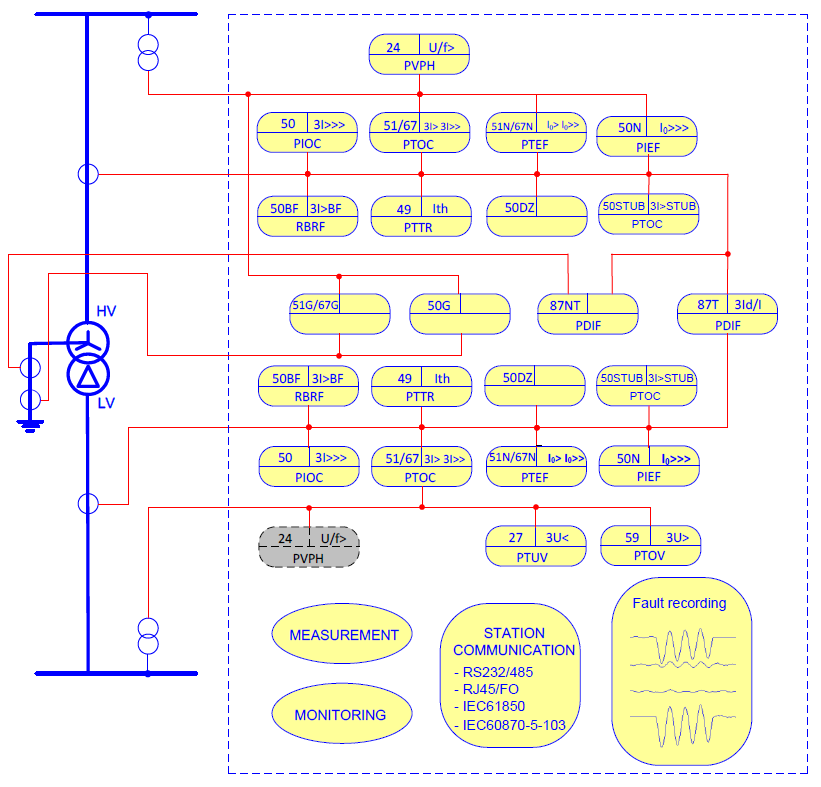

- Generator, GSU, ET Transformer Unit Protection System

- Analog inputs, Generator & Transformer- CT and VT

- Generator protection functions (87G, 40G, 78, 50S, 46, 51V, 49S, 59, 27, 21G, 32R, 50/27, 64GB, 64R, 47, 64s-95 &100%, 81 O&U, 24G)

- GSU Trans Protection Functions (87T, 87GT, 64T(87N), 51N, 50/51T)

- Excitation Trans Protection Functions (50.51ET, 49ET)

- Trip matrix, Blocking logic

- Binary Outputs, LED Signal, Output Contact test

- Disturbance recorder

- IEC 61850 Signals

Parameter setting and Relay calculations

- 87G Generator Differential Protection

- 87T GSU Trans. Differential Protection

- 87GT Overall Differential Protection

- 40G Generator Field Failure Protection

- 78G Generator Pole Slipping Protection

- 50S, Generator Split phase overcurrent protection

- 46 Generator Negative Phase Sequence Protection

- 51V Generator Voltage-Dependent O/C Protection

- 49S Generator Stator Overload Protection

- 59G Generator Overvoltage Protection

- 21G Generator Underimpedance Protection

- 27G Generator Undervoltage Protection

- 32R Generator Reverse Power Protection

- 64S Generator 95%&100% Stator Earth Fault Protection

- 51/27 Generator Dead Machine Protection

- 64GB Generator Busbar Earth Fault Protection

- 64R Generator Rotor Earth Fault Protection

- 81O Generator Overfrequency Protection

- 81U Generator Underfrequency Protection

- 24G Generator Overflux Protection

- 47G Generator Fuse Failure Supervision

- 50/51ET Excitation Trans. Overcurrent Protection

- 49ET Excitation Trans. Overload Protection

- 51N-GSU Gen. Step-up Trans. Neutral Point OvercurrentProtection

- 64T GSU Trans. Restricted Earth Fault Protection

- 50/51T GSU Trans. Over Current Protection

- 50/51SST Station Service Trans. Over Current Protection

Click here to enroll in the course and get the certificate of the IEC 61850 compilation course

https://elec-engg.com/iec-61850-training-course/

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1000: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1001: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1002: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1003: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1004: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1005: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1006: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1007: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1008: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1009: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1010: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1011: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1012: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1013: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1014: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1015: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1016: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1017: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1018: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1019: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1020: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1021: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1022: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1023: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1024: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1025: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1026: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1027: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1028: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1029: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1030: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1031: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1032: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1033: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1034: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1035: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1036: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1037: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1038: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1039: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1040: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1041: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1042: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1043: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1044: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1045: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1046: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1047: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1048: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1049: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1050: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1051: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1052:Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1053: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1054: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1055: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1056: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1057: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1058: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1059: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1060: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1061: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1062: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1063: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1064: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1065: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1066: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1067: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1068: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1069: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1070: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1071: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1072: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1073: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1074: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1075: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1076: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1077: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1078: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1079: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1080: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1081: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1082: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1083: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1084: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1085: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1086: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1087: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1088: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1089: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1090: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1091: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1092: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1093: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1094: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1095: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1096: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1097: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1098: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1099: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1100: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1101: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1102: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1103: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1104: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1105:Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1106: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1107: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1108: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1109: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1110:Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1111: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1112: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1113: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1114: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1115: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1116: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1117: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1118: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1119: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1120: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1121: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1122: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1123: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1124: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1125: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1126: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1127: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1128: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1129:Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1130: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1131: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1132: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1133: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1134: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1135: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1136: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1137: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1138: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1139: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1140: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1141: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1142: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1143: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1144: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1145: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1146: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1147: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1148: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1149: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1150: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1151: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1152: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1153: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1154: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1155: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1156: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1157: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1158: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1159: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1160: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1161: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1162: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1163: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1164: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1165: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1166: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1167: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1168: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1169: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1170: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1171: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1172: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1173: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1174: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1175: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1176: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1177: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1178: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1179: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1180: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1181: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1182: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1183: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C1184: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1185: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1186: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1187: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1188: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1189: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1190: Click here to download

- IEC 61850 TRAINING CERTIFICATE NUMBER C 1191: Click here to download

Training delivery: Face-to-face / Online sections on Google Meet + pre-recorded videos

Trainer: Dr. Saeed Roostaee

What you’ll learn

- Packet sniffing approaches and tools

- How to connect to switched network infrastructure to capture required data

- How to start with Wireshark and its basic settings

- How do you use capture and display filters in Wireshark?

- Tips and tricks on working with packets

- Tips and tricks on working with capture files

- How to analyze GOOSE, Sampled Values, and MMS traffic with Wireshark

- Practical examples

- Capture and interpret network traffic with Wireshark

- Understand core networking protocols – DHCP, DNS, TCP/IP

- Troubleshoot the top five network problems with Wireshark

- Analyze a cybersecurity attack with Wireshark

Content

Using Wireshark for traffic analysis in digital substations

- Introduction and Contents Overview

- Installing Wireshark and the Command Line Tools

- Introduction to packet sniffing and basics of communication protocols

- What are Wireshark Profiles and Why Should We Use Them?

- Hands-On with Wireshark

- Configuring Profiles, Adding Custom Columns

- Configuring the Wireshark Interface

- Making the right connections to start sniffing in a switched environment

- Start capturing with Wireshark and manage its basic settings

- Introduction to Wireshark Filters

Capture filters Vs display filters - Filtering for IP Addresses, Source or Destination

- Filtering for Protocols and Port Numbers

- Filtering for conversations

- Operators in display filters

- Working with packets

- Working with capture files

- Creating Display Filters in Wireshark

- Packets and the OSI Model

- Ethernet – The Frame Header

- Unicasts vs Broadcasts vs Multicasts

- The Internet Protocol – Learning the Header Values

- Following a Packet Through the Network – Re-Encapsulation

- Analyzing a Packet From Multiple Capture Points

- How IP Fragmentation Works

- The UDP Header Explained

- UDP Review

- Practical TCP – The Handshake

- Analyzing TCP Options

- How Sequence and Acknowledgement Numbers Work

- Slow application response time

- High Network Latency

- Network Packet Loss

- TCP Analysis Review

- Digital substation traffic capture analysis

- Practical demo with Wireshark

- Trainer: Dr. Saeed Roostaee (Profile)

- Pre-recorded videos with online access+Free updates +Free certification +Free technical support

Content:

Supplementary Files: The important related files/ videos /software and attached to the course as extra files.

Any queries, please feel free to contact me at: saeed61850@gmail.com

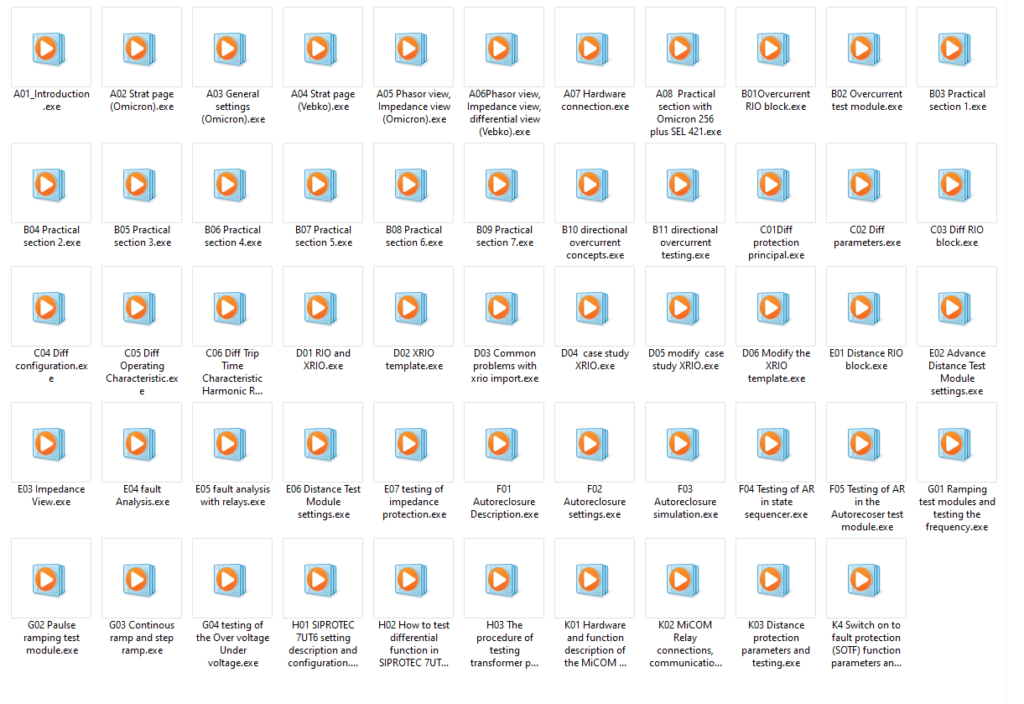

Part A: Introduction, general settings, Hardware & connection, Impedance/Vector/report View, the test object, …

- A 01 (Length: 02 min, Update: Oct 3, 2021): Introduction

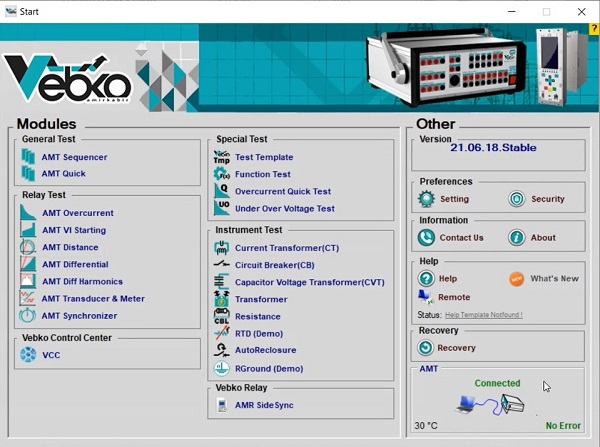

- A 02 (Length: 05 min, Update: Oct 3, 2021): Strat page (Omicron)

- A 03 (Length: 06 min, Update: Oct 3, 2021): General settings (Omicron)

- A 04 (Length: 05 min, Update: Oct 3, 2021): Strat page (Vebko)

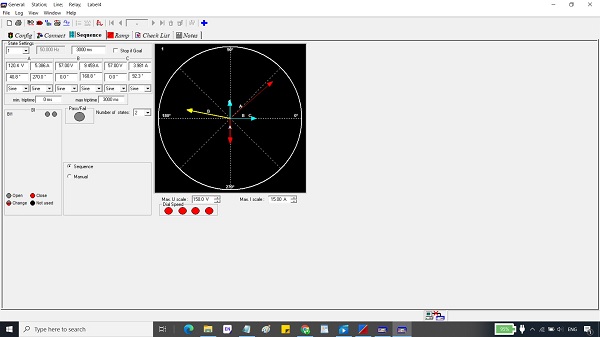

- A 05 (Length: 14 min, Update: Oct 3, 2021): Phasor view, Impedance view (Omicron)

- A 06 (Length: 06 min, Update: Oct 3, 2021): Phasor view, Impedance view, differential view (Vebko)

- A 07 (Length: 04 min, Update: Oct 3, 2021): Hardware connection

- A 08 (Length: 10 min, Update: Oct 3, 2021): Practical section with Omicron 256 plus, SEL 421

Part B: Overcurrent and Directional Overcurrent Functions (67, 67N, 50, 51, 50N, 51N)

- B 01 (Length: 19 min, Update: Oct 3, 2021): Test object, Overcurrent RIO block, testing of overcurrent

- B 02 (Length: 16 min, Update: Oct 3, 2021): Settings of the Overcurrent test module

- B 03 (Length: 15 min, Update: Oct 3, 2021): Practical section

- B 04 (Length: 17 min, Update: Oct 3, 2021): Practical section

- B 05 (Length: 06 min, Update: Oct 3, 2021): Practical section

- B 06 (Length: 15 min, Update: Oct 3, 2021): Practical section

- B 07 (Length: 09 min, Update: Oct 3, 2021): Practical section

- B 08 (Length: 15 min, Update: Oct 3, 2021): Practical section

- B 09 (Length: 22 min, Update: Oct 3, 2021): Practical section

- B 10 (Length: 23 min, Update: Oct 3, 2021): Practical section (directional overcurrent concepts, settings, practice)

- B 11 (Length: 06 min, Update: Oct 3, 2021): Practical section (directional overcurrent testing)

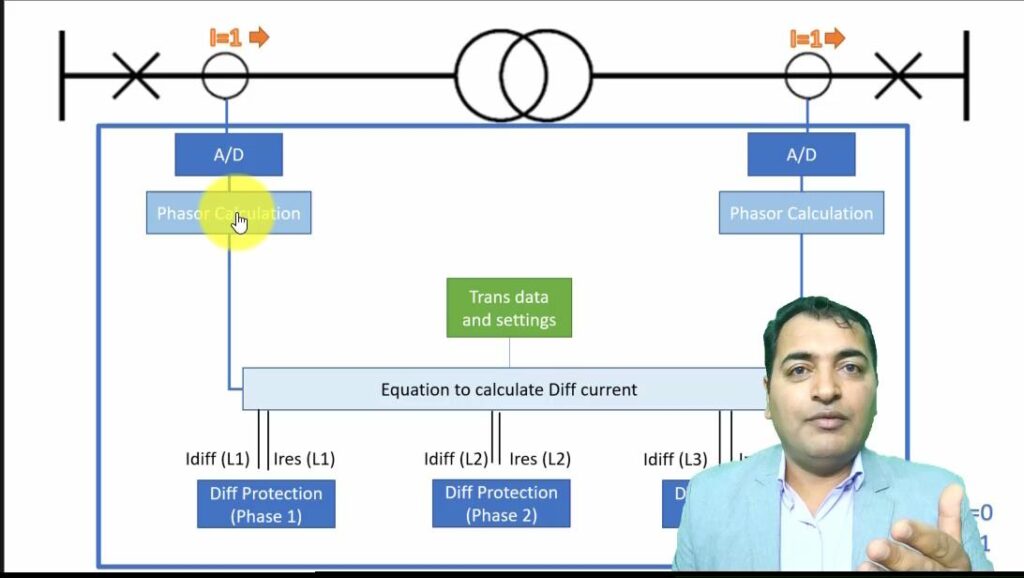

Part C: Differential Protection Functions (87G, 87T, 87L)

- C 01 (Length: 03 min, Update: Oct 27, 2021): Diff protection principal

- C 02 (Length: 11 min, Update: Oct 27, 2021): Diff parameters

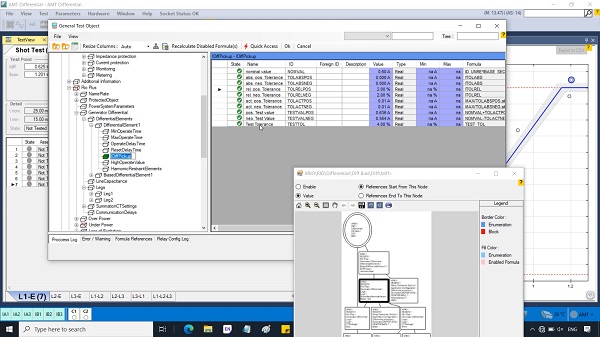

- C 03 (Length: 12 min, Update: Oct 27, 2021): Diff RIO block

- C 04 (Length: 05 min, Update: Oct 27, 2021): Diff configuration

- C 05 (Length: 07 min, Update: Oct 27, 2021): Diff Operating Characteristic

- C 06 (Length: 12 min, Update: Oct 27, 2021): Diff Trip Time Characteristic & Diff Harmonic Restraint

Part D: XRIO and PTL

- D 01 (Length: 13 min, Update: Nov 13, 2021): RIO and XRIO history and why we should use this format for relay testing, RIO structure, XRIO structure, Differences between RIO and XRIO files, XRIO features & benefits, LinkToXRIO

- D 02 (Length: 05 min, Update: Nov 13, 2021): XRIO template, How to Import Relay Settings, How to find a proper XRIO template and filter based on the relay

- D 03 (Length: 08 min, Update: Nov 13, 2021): Common problems while loading the relay settings into a template and how to solve the issues, XRIO template based on the relay versions

- D 04 (Length: 06 min, Update: Nov 13, 2021): Explain a case study XRIO file

- D 05 (Length: 10 min, Update: Nov 13, 2021): Modify a case study XRIO file

- D 06 (Length: 09 min, Update: Nov 13, 2021): Modify the XRIO template, RIO blocks

Part E: Impedance Protection Functions

- E 01 (Length: 09 min, Update: Nov 26, 2021): Distance RIO block

- E 02 (Length: 07 min, Update: Nov 26, 2021): Advance Distance Test Module settings

- E 03 (Length: 08 min, Update: Nov 26, 2021): Distance protection function principal, Impedance View

- E 04 (Length: 18 min, Update: Nov 26, 2021): Analysis of several faults visually in the impedance view

- E 05 (Length: 19 min, Update: Nov 26, 2021): Analysis of several distance relays (RAZOA, ABB REL670, SEL421, Siemens 7SA8x, MiCOM P442, NR PCS 931S, Protecta)

- E 06 (Length: 08 min, Update: Nov 26, 2021): Distance Test Module settings

- E 07 (Length: 12 min, Update: Nov 26, 2021): Preparing XRIO file for testing of impedance protection functions

Part F: Autoreclosure Function (ANSI 79)

- F 01 (Length: 04 min, Update: Dec 03, 2021): Autoreclosure Description, auto reclose process

- F 02 (Length: 05 min, Update: Dec 03, 2021): Autoreclosure settings, Autoreclose timing diagram

- F 03 (Length: 11 min, Update: Dec 03, 2021): Autoreclosure simulation

- F 04 (Length: 12 min, Update: Dec 03, 2021): Testing of AR in state sequencer

- F 05 (Length: 09 min, Update: Dec 03, 2021): Testing of AR in the Autorecoser test module

Part G: Voltage and Frequency Protection Functions (ANSI 27, ANS59, ANSI81O, 81U)

- G 01 (Length: 06 min, Update: Dec 08, 2021): Ramping test modules and testing the frequency functions

- G 02 (Length: 05 min, Update: Dec 08, 2021): Paulse ramping test module

- G 03 (Length: 06 min, Update: Dec 08, 2021): Continous ramp and step ramp

- G 04 (Length: 11 min, Update: Dec 08, 2021): How to test Over/Under voltage protection functions (59, 27)

Part H: Study functions, testing, and commission of SIPROTEC 7UT6

- H 01 (Length: 10 min, Update: Dec 20, 2021): SIPROTEC 7UT6 setting description and configuration

- H 02 (Length: 14 min, Update: Dec 20, 2021): How to test differential function in SIPROTEC 7UT6, No combined characteristic feature, Automate testing by creating SIEMENS 7UT XRIO file

- H 03 (Length: 18 min, Update: Jan 01, 2022): The procedure of testing transformer protection with Quick CMC

Part K: Study functions, testing, and commission of MiCOM P44x

- K 01 (Length: 19 min, Update: Oct 31, 2022): Hardware and function description of the MiCOM P441, P442 & P444

- K 02 (Length: 17 min, Update: Oct 31, 2022): MiCOM Relay connections, communication, and Wire connection test

- K 03 (Length: 05 min, Update: Nov 1, 2022): Distance protection parameters and testing

- K 04 (Length: 10 min, Update: Nov 1, 2022): Switch on to fault protection (SOTF) function parameters and testing

- …

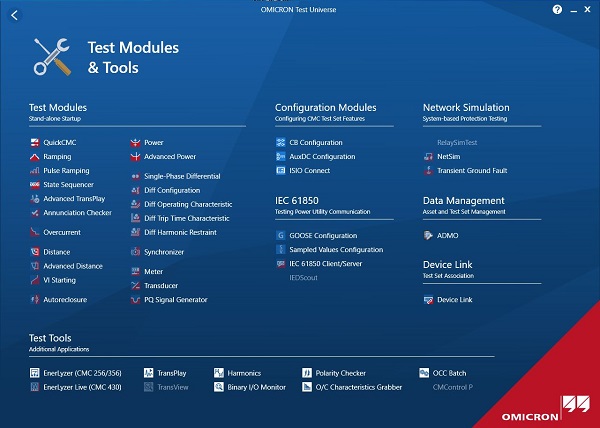

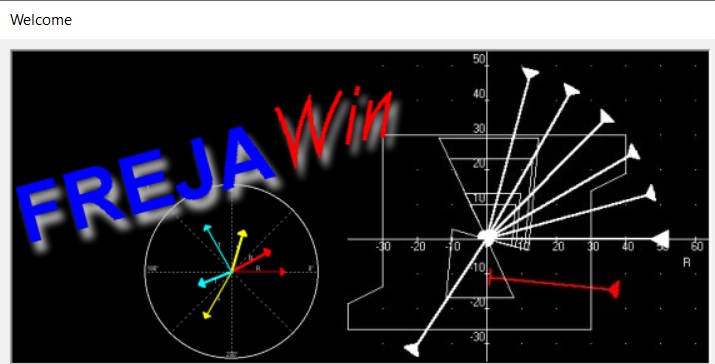

- Introduction, Software Installation, and general settings

- Different types of test modules

- Impedance/Vector/report View, Display settings

- Test Object, Hardware Configuration

- RIO, XRIO, and PTL

- Control Center, How to create and modify XRIO/ PTL files

- Transient module, Advanced transplay

- RIO Function Over Current, Define Element Characteristic, Pick-Up/ Drop-Off Test

- Testing of the Overcurrent and Directional Overcurrent Functions (67, 67N, 50, 51, 50N, 51N)

- Distance Configuration, Settings, Shot Test, Check Test, Search Test, Z\t Diagram, Zone Settings

- Testing of the Distance function (21)

- Principle of Differential Protection, Operating Characteristic, Differential Configuration, Differential Operating Characteristic, Differential Trip Time, and Harmonic Restraint

- Testing of the Differential protection function (87, 87G, 87T)

- Testing of the Power swing function

- Autoreclosure, shot and times, unsuccessful / Successful Sequence

- Testing of the Autorecloser function

- Testing of the Fault location function

- Testing of the Over/Under frequency (81O/ 81U)

- Testing of the Over/Undervoltage (59, 27)

- Testing of the Pole-Slip function (78)

- Testing of the Loss of Excitation (40)

- Testing of the Negative Phase Sequence (46)

- Testing of the Overload (49)

- How to test the distance function if the distance module is deactivated in the test universe software

- How to test differential function if the differential module is deactivated in the test universe

- Practical sections with testing of the relays (ABB REG670, MiCOM P441, MiCOM P123, …)

The testing & commissioning of the protection relays can be done by different testing software and hardware. In this training, we have used OMICRON Test Universe, Vebko AMpro, and FREJA win.

Impedance protection function testing is a critical process conducted to verify that the impedance relays or devices installed in a power system are functioning correctly and capable of accurately measuring and responding to changes in impedance levels. This testing involves injecting specific test signals into the relay, simulating various fault conditions, and comparing the relay’s response against expected outcomes to ensure its proper operation during actual fault scenarios. By rigorously testing the impedance protection function, power system operators can confirm the reliability and effectiveness of these protection schemes in safeguarding the electrical network against faults and maintaining system stability. Regular testing is essential to identify any potential issues or malfunctions that may compromise the protection system’s performance and integrity.

The Omicron CMC test kit is a versatile and reliable solution designed for testing various protection relay functions, including impedance, differential, overcurrent, and distance protection in power systems. This portable test kit offers a comprehensive range of testing capabilities, such as injecting signals, simulating fault conditions, and assessing relay responses, to ensure the accurate and effective operation of protection relays and related equipment. With its user-friendly interface, advanced functionalities, and high precision measurement capabilities, the Omicron CMC test kit is widely used by utilities, maintenance technicians, and protection engineers for testing and commissioning protection schemes, ensuring the reliability and performance of critical components in power systems.

The Omicron CMC test kit is a valuable tool for testing differential protection functions in power systems. By utilizing the test kit’s capabilities to inject specific test signals and simulate fault conditions, engineers can accurately assess the performance and reliability of the differential protection scheme. The advanced features and precise measurements offered by the Omicron CMC test kit enable users to verify that the protection relay operates correctly in detecting and isolating faults within the power system, ensuring the overall stability and protection of the electrical network. Conducting differential protection function testing with the Omicron CMC test kit helps to identify any potential issues, optimize the relay settings, and validate the effectiveness of the protection scheme in safeguarding the system against faults.

Need some experience people to join KBR-AMCDE, Oil and Gas, Al-Khobar, Saudi Arabia

About KBR-AMCDE

KBR-AMCDE is an entity formed to carry out general engineering and project management services under the Saudi Arabian Oil Company (Saudi Aramco) General Engineering Services Plus (GES+) initiative. KBR AMCDE provides front-end engineering and design (FEED), detailed design, procurement and project management services within the Oil & Gas industry. KBR-AMCDE specializes in front-end engineering design (FEED), detailed design, material procurement, and project management services (PMS). With extensive resources and technology, we deliver quality engineering packages to clients in Kingdom and overseas.

If you are qualified and experienced in PSCAD, please contact Mr. Narayanan Sivakumar with the below details:

Linkedin profile: linkedin.com/in/narayanan-sivakumar-95b80515

Email ID: narayanansivakumar1985@gmail.com

- Trainer: Dr. Saeed Roostaee (Profile)

- Pre-recorded videos

- The demo is available based on the request

- Course creation 8 April 2023

- Last update: 10 June 2023

- Total hours: 6 hrs and 17 min till 10 June 2023

- The updates will be added for free and no expiration.

Chapter I: Transformer Introduction

- Course introduction and transformer history (13 min)

- Concepts of the Electric Power Transmission Transformers (10 min)

- How does a Transformer work part I (7 min)

- How does a Transformer work part II (4 min)

- Transformer Parts and Functions (28 min)

- Single-phase and three-phase transformers (2 min)

- Transformer shipping and installation (9 min)

- Large Transformer Transportation (1 min)

- Transformer Equivalent Circuit (5 min)

- Why do we need an equivalent circuit (5 min)

- The Series Components (8 min)

- The Shunt Components (6 min)

- The Internal Ideal Transformer (4 min)

- Simplifying the Transformer Equivalent Circuit Part I (6 min)

- Simplifying the Transformer Equivalent Circuit Part II (4 min)

- Simplifying the Transformer Equivalent Circuit Part III (6 min)

- Vector Group Connections (15 min)

Chapter II: Transformer Faults

- Power Transformer Faults (3 min)

- Top 10 Transformer Blasts and Short Circuits (15 min)

- Power Transformer Explosion Incidents & Reasons & Precautionary Measures (4 min)

- Winding & Terminal Failures (4 min)

- The Effect of Through Faults on Power Transformers (4 min)

- Tap Changer (OLTC) Failure (3 min)

- Transformer bushings How it works (1 min)

- High Voltage bushing Faults early Detection and bushing monitoring (36 min)

- Why is Online Transformer Bushing Monitoring So Important (3 min)

- Transform Miscellaneous Failures (3 min)

- Why do we need Transformer Protection? (2 min)

- How do we Protect Transformers? (9 min)

- GE Transformer Protection& Control IED (2 min)

- SEL 787 & ABB RET 670 (14 min)

Chapter III: Transformer Protection Functions

- Differential Protection Part I (16 min)

- Transformer Differential Protection Part II (14 min)

- Differences between digital transformer differential relays (7 min)

- Simulate different cases and test the differential transformer protection function (9 min)

- Restricted Earth Fault Protection(REF) in Transformer (7 min)

- High Impedance Restricted Earth Fault Protection working principle (7 min)

- Stability Resistance and Metrosil Resistance in REF Protection (12 min)

- Low impedance REF (8 min)

- Buchholz relay (4 min)

- Transformer Buchholz Protection Relay principal (2 min)

- Inside the Buchholz relay (4 min)

- Buchholz relay by MR (5 min)

Chapter IV: Transformer Protection Relay IEDS

- ABB RET 670 Hardware structure (11 min)

- ABB RET 670 Transformer Protection Application template (6 min)

- ABB RET 670 Configuration and T2WPDIF Function block (12 min)

- ABB RET 670 Parameters and T2WPDIF parameters (11 min)

- Simulation of the differential protection algorithm in the ABB RET 670 relays (12 min)

SIEMENS 7UT85 configuration

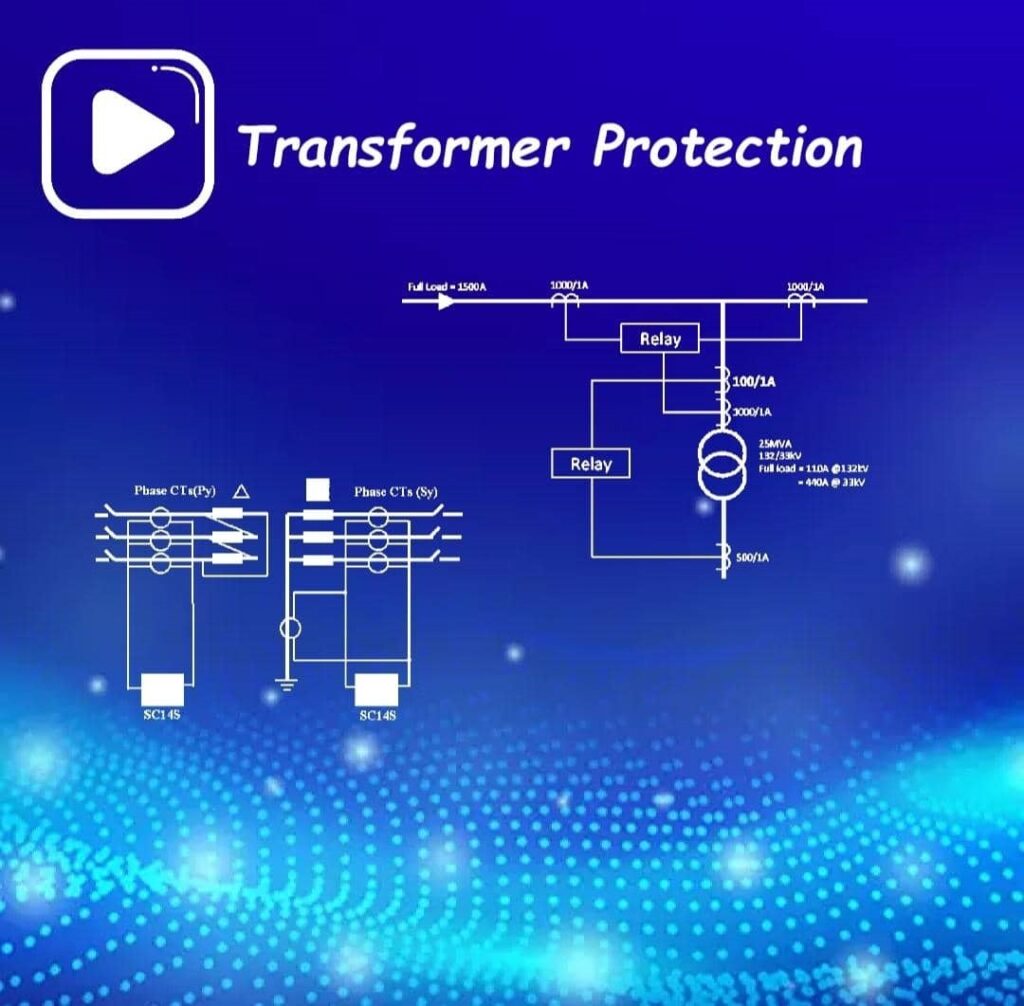

How to enroll in this training course (How to access transformer protection training course):

1- Check out the Transformer Protection Training with the below link (https://elec-engg.com/product/transformer-protection-training/)

2- we will complete your order by sending your license to access the videos (https://elec-engg.com/how-to-access-our-training-courses/)

ِDemo is available

Transformer Protection Training

- Trainer: Dr. Saeed Roostaee (Profile)

Course details and samples on: https://elec-engg.com/transformer-protection-training-video/

- Trainer: Dr. Saeed Roostaee (Profil…

The ABB RET 670 is a numerical generator protection relay designed to provide comprehensive protection and control functions for generators in power plants and other industrial applications. The device offers a wide range of protection features, such as overcurrent, voltage, frequency, and differential protection, as well as advanced functions for grid synchronization and monitoring. With its high-speed processing capabilities and advanced communication options, the RET 670 ensures reliable and efficient protection of generators, helping to enhance system reliability and prevent equipment damage during fault conditions.

Restricted Earth Fault (REF) protection in transformers is a differential protection scheme that detects earth faults within the transformer windings by comparing the current entering and leaving the transformer. The system uses current transformers to measure and compare the current flow, and if an imbalance is detected, it indicates the presence of a fault within the transformer. REF protection is designed to provide fast and reliable detection of earth faults, enabling the disconnection of the transformer from the system to prevent damage and ensure the safety of personnel and equipment. This advanced protection scheme is essential for maintaining the integrity and operational efficiency of transformers in power systems.

Transformer Differential Protection is a crucial element in safeguarding transformers from internal faults. By comparing the current entering and exiting the transformer windings using current transformers, this protection scheme can detect any imbalance that signifies a fault. If a fault is detected, the system initiates a trip signal to isolate the transformer from the network, preventing further damage. Differential protection is vital for ensuring the operational integrity of transformers and enhancing system reliability by swiftly isolating faults and minimizing downtime. It plays a critical role in maintaining the performance and longevity of transformer assets in power systems.

The Siemens 7UT85 is a numerical transformer protection relay that offers advanced protection features for medium and high-voltage transformers. It is equipped with various protection functions such as differential, overcurrent, and restricted earth fault protection, ensuring reliable and comprehensive protection for transformers. The 7UT85 is designed to provide accurate fault detection and fast response times to safeguard transformers from internal faults, helping to maintain system reliability and operational efficiency. With its flexible configuration options and integrated communication capabilities, the Siemens 7UT85 is a versatile and effective solution for transformer protection in power systems.

The Buchholz relay is a protective device used in oil-filled electrical equipment, such as transformers and tap changers, to detect and respond to faults and abnormalities in the oil insulation system. This relay operates based on the principle of gas accumulation in the oil. When a fault occurs within the equipment, such as a partial discharge or overheating, gas is generated, leading to increased pressure in the oil. The Buchholz relay is triggered by this pressure build-up and sends a signal to isolate the equipment to prevent further damage. Additionally, the relay can provide early warning of developing faults, allowing for proactive maintenance to be carried out. Overall, the Buchholz relay serves as a critical component in ensuring the safety and reliability of oil-filled electrical equipment.

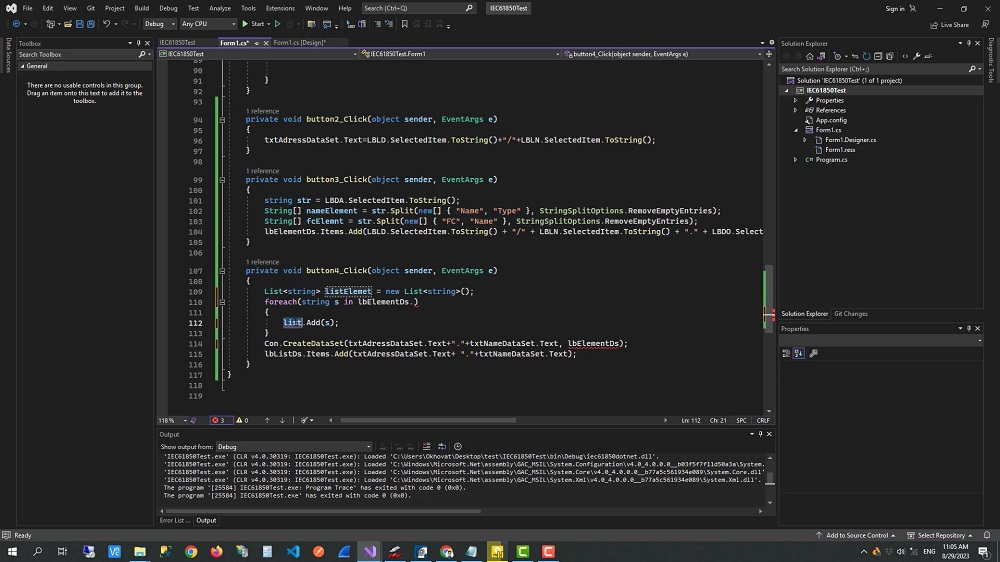

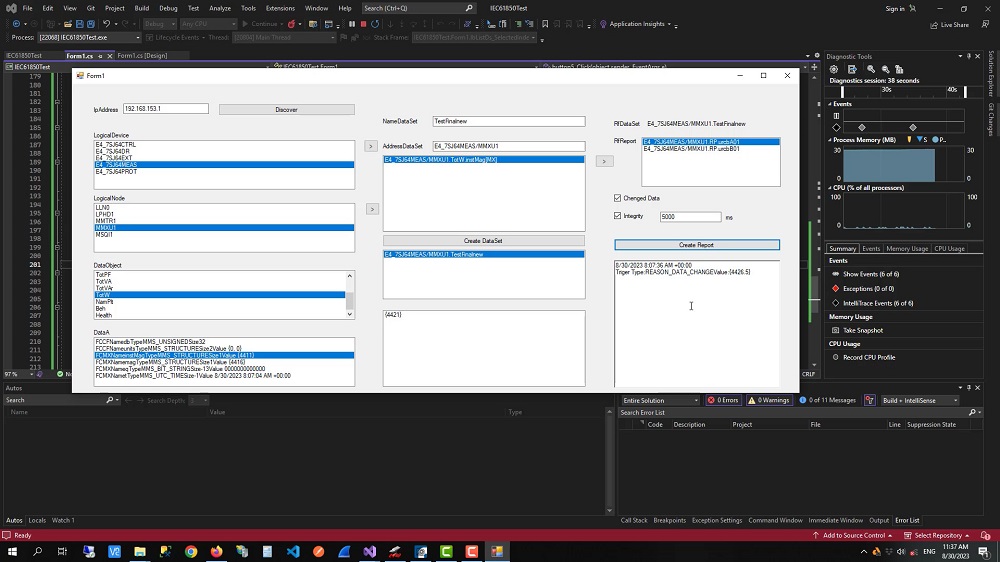

Overview

The IEC 61850 source code library allows a fast and cost-efficient implementation of the IEC 61850 protocols (MMS, GOOSE, Sampled Values) into devices and applications. The APIs are designed to be very easy to use. The basic library is written in C (C99 compliant to provide maximum portability). Due to its hardware and platform-independent design, it can quickly deploy on any platform.

C#.NET Component

The C# library allows the creation of a managed DLL component that can easily be deployed in .NET applications. It is a wrapper of the C library. It can be used to be integrated into GUI applications, SCADA systems …

- Compatible with .NET and Mono

- Runs on Windows, Linux, and other platforms supported by .NET and Mono

- Very easy-to-use API

- Support for MMS client/server

- Support for GOOSE/SV subscribers

Features Source Code Library

- Easy to use IEC 61850 oriented API

- MMS, GOOSE, and Sampled Measured Values (SMV)

- TLS support

- Support editions 1, 2, and 2.1 of the standards

- Configurable generation of server data models from SCL/CID file at runtime

- Peer-reviewed and secure source code

- C library (C99) with C and C#/.NET API

Source codes that you see in this package:

- MMS client/server, GOOSE (IEC 61850-8-1)

- Sampled Values (SV – IEC 61850-9-2)

- Support for buffered and unbuffered reports

- Online report control block configuration

- Data access service (get data, set data)

- online data model discovery and browsing

- all data set services (get values, set values, browse)

- dynamic data set services (create and delete)

- log service

- flexible API to connect custom databases

- comes with sqlite implementation

- MMS file services (browse, get the file, set file, delete/rename the file)

- download COMTRADE files

- upload firmware or configuration files

- Setting group handling

- Service tracking (v1.5)

- GOOSE and SV control block handling

- TLS support

Application That can create with this library:

- Communications in Substations (MMS/GOOSE/SV)

- Communications for Wind Power Plants (IEC 61400-25)

- Communications for Decentralized Energy Resources (DER – IEC 61850-420)

- Intelligent Electronic Devices (IED)

- Measurement Devices

- SCADA Systems

- Monitoring

- Test systems

Easy programming and development of Scada and Monitoring System for protection Relays and other devices that compatible with IEC 61850 Standard with this package

- IEC 61850 Programming with C#

- Pre-recorded sessions: 4 hours

In this course, you will learn the principles of IEC 61850 programming and building monitoring and SCADA systems for networks that use IEC 61850 protection relays or IEDs (Intelligent Electronic Devices). To do so, first, you will learn about the IEC 61850 standard, including the concept of this standard, the simulation of the IEC 61850 GOOSE, and the IEC 61850 MMS reports. And how to read or write data and control commands to IEDs.

Next, you will learn Programming in IEC61850 Standard. In this chapter, you will learn how to use the IEC61850 Libraries for Programming in C# Language which are prepared by us and attached to the course as a gift. Then you will learn how to write a code for discovering and reading the substation IEDs, Functions, and Data Models. After that, you will learn how to write code to create DataSet and Report from the Data Models and set trigger options.

Course Content:

- Basics of IEC61850

- Sample Value

- GOOSE Protocol

- MMS Protocol

- Simulation of IEC 61850 Data Models

- Simulation of IEC 61850 DataSet

- Simulation of IEC 61850 GOOSE

- Simulation of IEC 61850 MMS

- Programming in IEC61850 Standard

- Necessary Libraries for Programming to C# Language in IEC61850 Standard

- Discovering Substation IEDs, Functions, and Data Models

- Read Data from Substation IEDs (Protection Relays,…)

- Create DataSet From Functions and Data Models and Read This DataSet

- Create a Report and Set Triggers

- Conclusion

Learn programming SCADA software based on IEC 61850 for your station as you like!

Supplementary Files:

- Source Code and Library for IEC 61850

- Visual Studio Code for Developers 2023

- C# Ultimate Guide – Beginner to Advanced

- FUNDAMENTALS OF COMPUTER PROGRAMMING WITH C#

- IEC 61850 Communication Networks and Systems In Substations: An Overview for Users

- Click here to download supplementary files

Source Code and Library for IEC 61850

The IEC 61850 source code library allows a fast and cost-efficient implementation of the IEC 61850 protocols (MMS, GOOSE, Sampled Values) into devices and applications. The APIs are designed to be very easy to use. The basic library is written in C (C99 compliant to provide maximum portability). Due to its hardware and platform-independent design, it can quickly deploy on any platform.

The C# library allows the creation of a managed DLL component that can easily be deployed in .NET applications. It is a wrapper of the C library. It can be used to be integrated into GUI applications, SCADA systems …

- Compatible with .NET and Mono

- Runs on Windows, Linux, and other platforms supported by .NET and Mono

- Very easy-to-use API

- Support for MMS client/server

- Support for GOOSE/SV subscribers

Features Source Code Library

- Easy to use IEC 61850 oriented API

- MMS, GOOSE, and Sampled Measured Values (SMV)

- TLS support

- Support editions 1, 2, and 2.1 of the standards

- Configurable generation of server data models from SCL/CID file at runtime

- Peer-reviewed and secure source code

- C library (C99) with C and C#/.NET API

Source codes that you see in this package:

- MMS client/server, GOOSE (IEC 61850-8-1)

- Sampled Values (SV – IEC 61850-9-2)

- Support for buffered and unbuffered reports

- Online report control block configuration

- Data access service (get data, set data)

- online data model discovery and browsing

- all data set services (get values, set values, browse)

- dynamic data set services (create and delete)

- log service

- flexible API to connect custom databases

- comes with sqlite implementation

- MMS file services (browse, get the file, set file, delete/rename the file)

- download COMTRADE files

- upload firmware or configuration files

- Setting group handling

- Service tracking (v1.5)

- GOOSE and SV control block handling

- TLS support

Application that can be created with this library:

- Communications in Substations (MMS/GOOSE/SV)

- Communications for Wind Power Plants (IEC 61400-25)

- Communications for Decentralized Energy Resources (DER – IEC 61850-420)

- Intelligent Electronic Devices (IED)

- Measurement Devices

- SCADA Systems

- Monitoring

- Test systems

Easy programming and development of Scada and Monitoring System for protection Relays and other devices that compatible with IEC 61850 Standard with this package

Keywords:

- IEC61850 Standard Communication Protocol Fundamentals

- IEC61850 Standard Standard Communication Protocols Simulation

- Programming for IEC61850 Standard Protocols

- Detect, Read, and Write values on IEDs (Relay Protections, Power Management, Meterings,…)

- IEC 61850 Programming

- IEC 61850 C# Programming in Visual Studio

- IEC 61850 SCADA Programming

- IEC 61850 MMS Programming

Reference Publication Type Title Value-added products Current Version

- IEC TS 61850-1-2: 2020 TS Part 1-2: Guideline on extending IEC61850 2020

- IEC TS 61850-1-2: 2020/AMD1:2022 TS Part 1-2: Guideline on extending IEC61850 Amendment 1 Consolidated Version 2022

- IEC TS 61850-2: 2019 TS Part 2: Glossary 2019

- IEC 61850-7-1: 2011/AMD 1: 2020 IS Part 7-1: Basic communication structure – Principles and models Amendment 1 Consolidated Version 2020

- IEC 61850-7-2: 2010/AMD 1:2020 IS Part 7-2: Basic information and communication structure – Abstract communication service interface(ASCI) Amendment 1 Consolidated Version 2020

- IEC 61850-7-3: 2010/AMD1:2020 IS Part 7-3: Basic communication structure – Common data classes Amendment 1 Consolidated Version 2020

- IEC 61850-7-4: 2010/ AMD 1: 2020 IS Part 7-4: Basic communication structure – Compatible logical node classes and data object classes Amendment 1 Consolidated Version 2020

- IEC TR 61850-7-5: 2021 TR Part 7-5: IEC 61850 modelling concepts 2021

- IEC TR 61850-7-6: 2019 TR Part 7-6: Guideline for definition of Basic Application Profiles (BAPs) using IEC61850 2019

- IEC TS 61850-7-7: 2018 TS Part 7-7: Machine processable format of IEC 61850-related data models for tools 2018

- IEC TS 61850-7-7: 2018/ AMD 1: 2023 TS Part 7-7: Machine processable format of IEC 61850-related data models for tools Amendment 1 Consolidated Version 2023

- IEC 61850-7-410: 2012 IS Part 7-410: Basic communication structure – Hydroelectric power plants – Communication for monitoring and control 2012

- IEC 61850-7-410: 2012/AMD 1: 2015 IS Part 7-410: Basic communication structure – Hydroelectric power plants – Communication for monitoring and control Amendment 1 Consolidated Version 2015

- IEC 61850-7-420: 2021 IS Part 7-420: Basic communication structure – Distributed energy resources and distribution automation logical nodes. 2021

- IEC TR 61850-7-500: 2017 TR Part 7-500: Basic information and communication structure – Use of logical nodes for modeling application functions and related concepts and guidelines for substations. 2017

- IEC TR 61850-7-510: 2021 TR Part 7-510: Basic communication structure – Hydroeletcric power plants, steam and gas turbines – Modelling concepts and guidelines. 2021

- IEC 61850-8-1: 2011/AMD1:2020 IS Part 8-1: Specific communication service mapping (SCSM) – Mappings to MMS (ISO 9506-1 and ISO 9506-2) and to ISO/IEC 8802-3 Amendment 1 Consolidated Version 2020

- IEC 61850-8-2:2018 IS Part 8-2: Specific communication service mapping (SCSM) – Mappings to extensive Messaging Presence Proptocol (XMPP). 2018

- IEC 61850-9-2: 2011/AMD1:2020 IS Part 9-2: Specific communication service mapping (SCSM) – Sampled values over ISO/IEC 8802-3 Amendment 1 Consolidated Version 2020

- IEC/IEEE 61850-9-3:2016 IS Part 9-3:Precision time protocol profile for power utility automation. 2016

- IEC 61850-10: 2012 IS Part 10: Conformance testing 2012

- IEC TR 61850-10-3:2022 TR Part 10-3: Functional testing of IEC 61850 systems. 2022

- IEC TS 61850-80-1:2016 TS Part 80-1: Guideline to exchanging information from a CDC-based data model; using IEC 60870-5-101 or IEC 60870-5-104 2016

- IEC TR 61850-80-3:2015 TR Part 80-3: Mapping to web protocols – Requirements and technical choices 2015

- IEC TS 61850-80-4:2016 TS Part 80-4: Translation from the COSEM object model (IEC 62056) TO the IEC 61850 data model 2016

- IEC TR 61850-90-1:2010 TR Part 90-1: Use of IEC 61850 for the communication between substations 2010

- IEC TR 61850-90-2:2016 TR Part 90-2: Using IEC 61850 for communication between substations and control centres 2016

- IEC TR 61850-90-3:2016 TR Part 90-3: Using IEC 61850 FOR condition monitoring diagnosis and analysis 2016

- IEC TR 61850-90-4:2020 TR Part 90-4: Network engineering guidelines 2020

- IEC TR 61850-90-5:2012 TR Part 90-4: Use of IEC 61850 to transmit synchrophasor information according to IEEE C37.118 2012

- IEC TR 61850-90-6:2018 TR Part 90-6: Use of IEC 61850 for Distribution Automation Systems 2018

- IEC TR 61850-90-7:2013 TR Part 90-7: Object models for power converters in dictributed energy resources (DER) systems. 2017

- IEC TR 61850-90-8:2016 TR Part 90-8: Object model for E-mobility 2016

- IEC TR 61850-90-9:2020 TR Part 90-9: Use of IEC 61850 for Electrical Energy Storage Systems 2020

- IEC TR 61850-90-10:2017 TR Part 90-10: Models for scheduling 2017

- IEC TR 61850-90-11:2020 TR Part 90-11: Methodologies for modelling of logics for IEC 61850 based applications 2020

- IEC TR 61850-90-12:2020 TR Part 90-12: Wide area network engineering guidelines 2020

- IEC TR 61850-90-13:2021 TR Part 90-13: Deterministic network technologies 2021

- IEC TR 61850-90-14:2021 TR Part 90-14: Using IEC 61850 FOR facts (flexible alternate current transmission systems), HVDC (high voltage direct current) transmission and power conversion data modelling 2021

- IEC TR 61850-90-16:2021 TR Part 90-16: Requirements of system management for Smart Energy Automation 2021

- IEC TR 61850-90-17:2017 TR Part 90-17: Using IEC 61850 to transmit power quality data. 2017

- Trainer: Dr. Saeed Roostaee (Profile)

- Face-to-face training

- Location & Fee: please contact us

- Duration: 10 days

Topics:

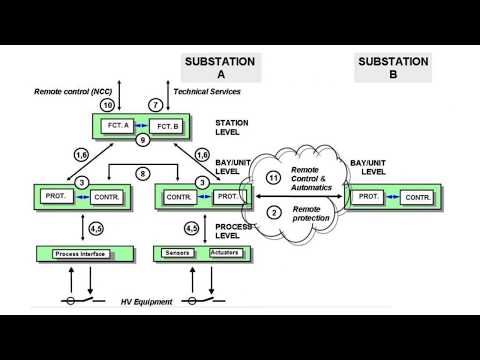

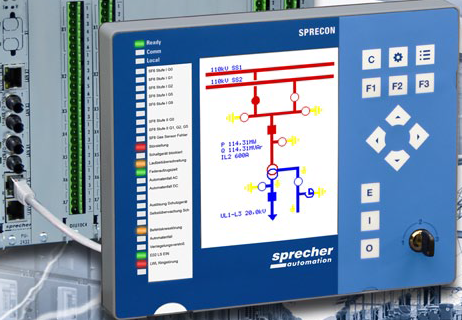

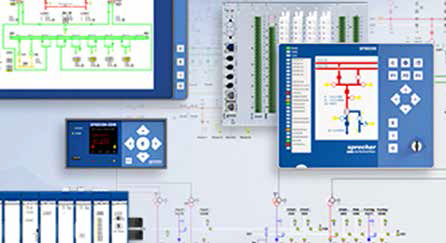

Substation Automation System:

- Substation Automation- Overview

- SAS Introduction

- SAS history

- SAS future

- Substation Automation Functions

- Process level

- Bay level

- Station Level

Network & Ethernet:

- Ethernet Concepts

- Fundamentals of Communication Via Ethernet

- Network Theory

- Components of the Network

- Fundamentals of Communication Via Ethernet Various Topologies

- Important Factors for Choosing a Topology

- Required Redundancy

- Distances Between Devices and Physical Dimensions of a Network

- Price Consideration

- Simple (Pure) Star

- Star Topology with Double Take

- Ring and Star Combination

- Economical Ring Solution With Only one External Switch

- Ring Topology With Two External Switches

- Commonly Used Configurations

- One Ring and Several Stars (most Frequently Occurring Topology)

- Two Rings Fitted into Each other

- Two Rings Connected Via a Double Main Ring

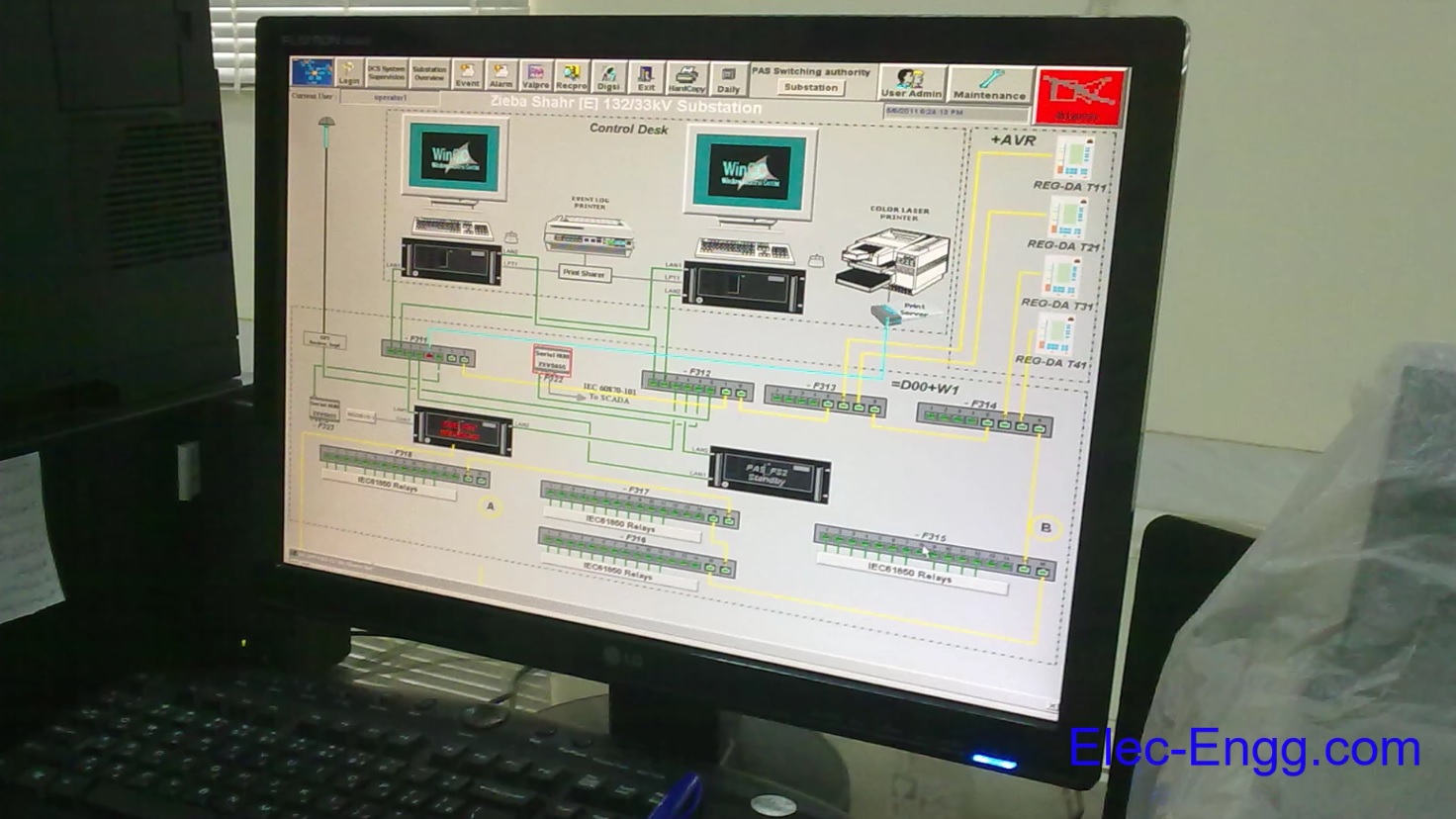

- Introduction: Provide an overview of SICAM PAS system

- Install SICAM PAS software and System components

- The new project, PAS Operation and Configure an IEC 103 interface

- How to use Device Descriptions (files)

- How to use the SICAM Value Viewer

- Configure an IEC 101 interface and T101 slave interfaces

- Configure an IEC 104 interface, T104 interface

- Introduction to IEC61850

- Creating a DIGIS database for a siprotec relay

- IEC61850 system configurator

- Data export and import

- Configure an IEC 61850 interface

- Normalization, Normalizing measured values

- Configure a PAS CC interface, Configuring an HMI interface

- Connect an IEC 61850 IED

IEC 61850:

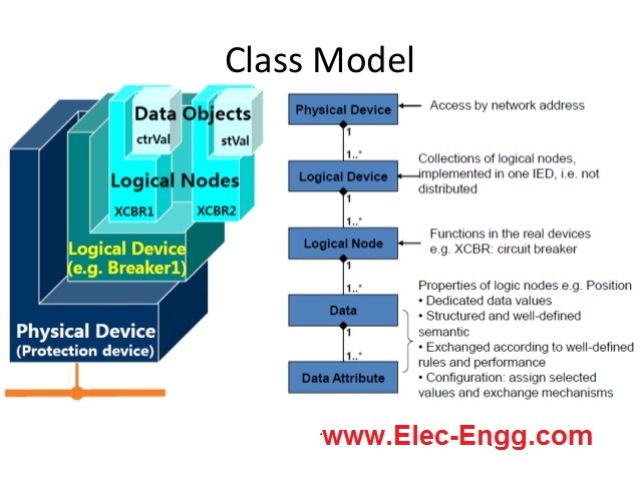

- IEC 61850 Concepts

- An Introduction to IEC 61850

- IEC 61850 data structure and data format

- Information Modeling

- Interoperability

- Architecture: Station & Process Buses

- Logical Nodes

- ACSI – Class Models

- DataSet

- Communication models

- Controls

- GOOSE / GSSE

- Client / Server

- Data Reporting & Logging

- Sampled Values

- Time Synch

- GOOSE & Ethernet Frames

- 7-OSI Layers & Client / Server

- MMS Protocol

- ASN.1 Encoding & Message Parsing

- SCL Syntax and Semantics

- .ICD/.CID Files: IED definitions

- .SCD File: Substation Section

- Access Points & Communications

- EC 61850 station in DIGSI 5 and IEC 61850 System Configurator

- Time synchronization settings and SNTP configuration

- IEC 61850 configuration in DIGSI 4

- GOOSE configuration and the publisher/subscriber LNs

- GOOSE simulation via IEDScout

- Sample IEC61850 Configuration & Parameterization of a SIPROTEC 4 Device (BCU)

SIEMENS SAS

- Introduction to SICAM PAS Automation System

- Fields of Application

- Hardware Configuration

- Setting the Interface Parameters

- Setting for Time Synchronization

- Configuration of IEC 61850 Network

- Inter Bay Communication GOOSE

- Modbus Connection of Measuring Centers (EMA90)

- RS484 Bus Connection

- EMA90 Connection Setting

- Setting the Network Parameters for Ethernet Switches

- Configuration of General Parameters of Ethernet Switches

- Configuration of RSTP Bridge & RSTP Port Parameters

- Configuration of SNMP Users, Group, and Access

- 7XV6555 Serial/Ethernet Converter

- 7XV5655 Configuration Tool

- 7XV5655 Parameterization

- GPS Satellite Clock

- Server Type of Satellite Clock

- PCI Card type of Satellite Clock

- Station Level Engineering

- SICAM PAS Installation System Types

- Demo Version

- Licensed Version

- Installation Requirements

- SICAM PAS Configuration Working with Project Databases

- SICAM PAS UI-Operation

- SICAM PAS Value Viewer

- SICAM PASCC

- Introduction to SICAM PASCC Control Center

- Overview of SICAM PAS CC

- SICAM PASCC

- Starting The WinCC/PASCC Software

Practical Section

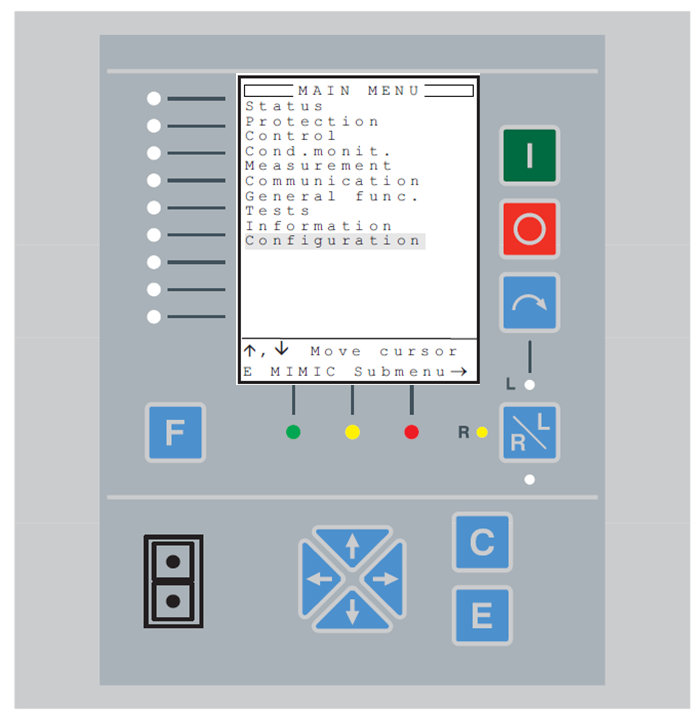

working with SIPROTEC 5 multifunction relay IED 7SX800

SICAM PAS stands for “Substation Automation System Process Automation Station,” which is a comprehensive solution for monitoring, controlling, and automating various processes in substations. It is designed to improve the efficiency, reliability, and safety of electrical substations by providing real-time data and advanced automation functionalities. Sicam PAS helps operators to manage and optimize their substation operations effectively, ultimately enhancing overall system performance.

SICAM PASCC is an advanced control center solution offered by Siemens for power utility operators. It provides real-time monitoring, control, and management capabilities for power grids and substations, helping operators make informed decisions and improve the overall reliability and efficiency of the electrical network. SICAM PASCC enables integration with various systems and devices, allowing for comprehensive centralized control and visualization of the grid operations. It plays a crucial role in ensuring smooth and secure power supply to customers by optimizing grid performance and response to fluctuations in demand or supply.

SICAM PAS UI-Operation is a user interface component of the Substation Automation System Process Automation Station (SICAM PAS) developed by Siemens. It provides operators with a graphical interface to monitor and control substation processes, enabling them to oversee system status, analyze data, and take necessary actions to ensure smooth operations. The UI-Operation module enhances operator efficiency by presenting relevant information in a user-friendly format, allowing for quick decision-making and effective management of substation activities.

WinCC and PASCC are both supervisory control and data acquisition (SCADA) software solutions developed by Siemens, but with different focuses and capabilities. WinCC is a general-purpose SCADA software that is widely used in various industries for monitoring and controlling processes, machinery, and equipment. It is versatile and highly customizable, with features for visualization, data logging, alarming, and historical trending. On the other hand, PASCC (Process Automation System Condition and Control) is specifically designed for the power utility sector, offering advanced functionalities tailored for monitoring, controlling, and managing power grid operations. PASCC provides specialized tools for real-time monitoring of substations, energy management, and grid optimization, making it a comprehensive solution for the unique requirements of power utilities. Ultimately, the choice between WinCC and PASCC would depend on the specific needs and industry focus of the user.

The SICAM PAS Value Viewer is a component of the SICAM PAS system developed by Siemens, designed to provide users with a comprehensive view of data values and parameters within the substation automation system. Through the Value Viewer, operators can access real-time information, historical data, and status updates to monitor and analyze the performance of the substation equipment. This tool enables users to make informed decisions, troubleshoot issues efficiently, and optimize the operation of the substation by leveraging the data visualization capabilities of SICAM PAS.

Information

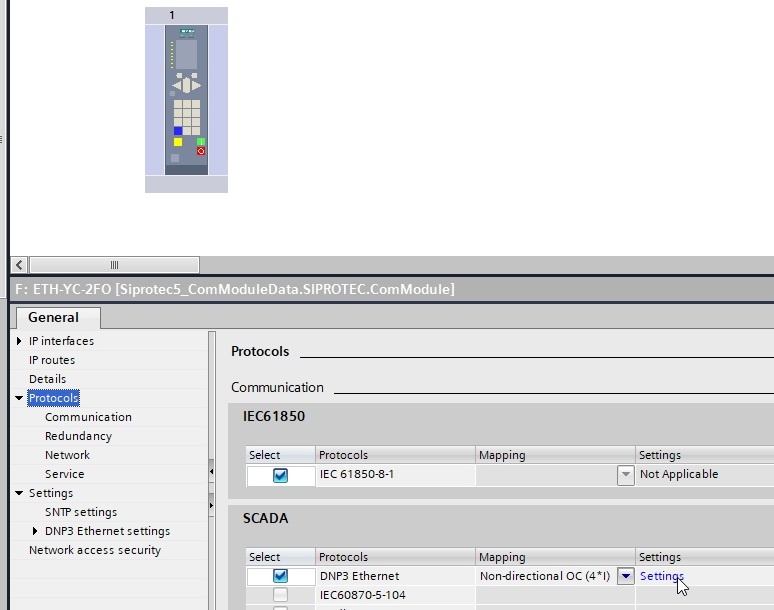

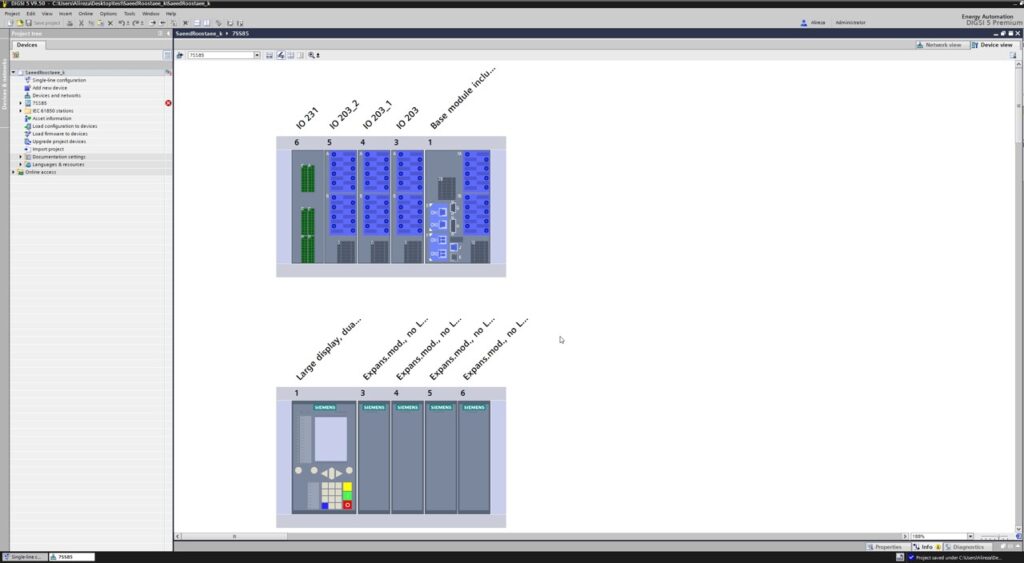

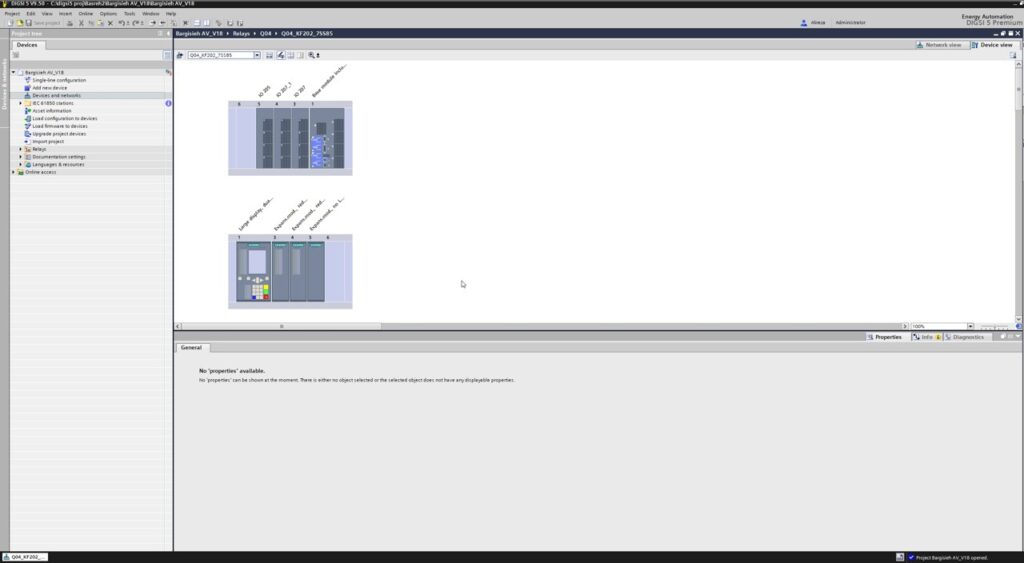

- Course Name: SIPROTEC 5 and DIGSI 5 (advanced)

- Trainer: Dr. Saeed Roostaee

- Format: Pre-recorded videos (demo is available)

- Course creation: June 2023

- Last update: July 2023

Note: This course can also be held either Online or Face to face based on the request

Course Structure:

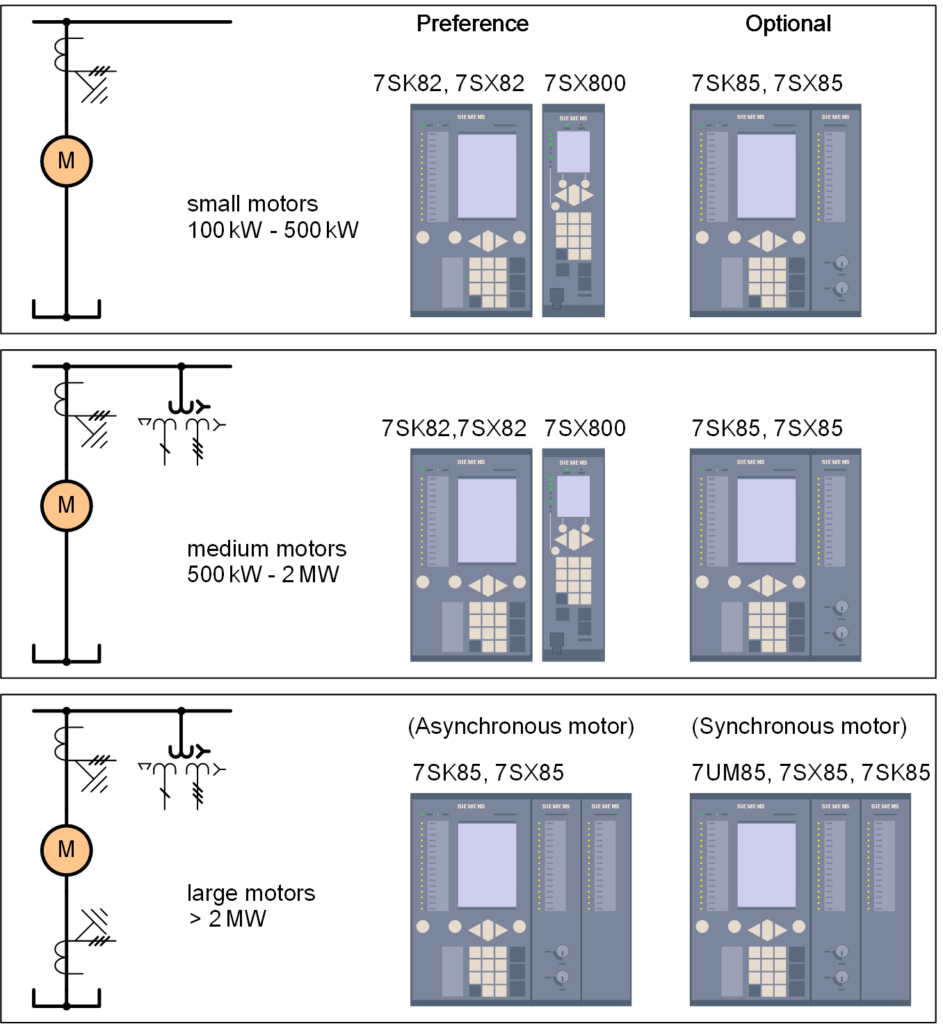

- Module 1: SIPROTEC 5 Hardware and ordering

- Module 2: Starting with DIGSI 5

- Module 3: Working with SIPROTEC 5 in online mode

- Module 4: System Functions

- Module 5: Function Groups

- Module 6: SIPROTEC 7SJ8

- Module 7: SIPROTEC 7SA8

- Module 8: SIPROTEC 7UT8

- Module 9: SIPROTEC 7SS8

- Module 10: SIPROTEC 7SK8

- Module 11: SIPROTEC 7VK8

- Module 12: SIPROTEC 7SD8

- Module 13: SIPROTEC 7SL8

- Module 14: SIPROTEC 7SX8

- Module 15: SIPROTEC 7UM8

- Module 16: SIPROTEC 7MD8

- Module 17: Functions and Settings

- Module 18: Signals and Masking IO

- Module 19: CFC

- Module 20: Control Functions

- Module 21: Display Page configuration

- Module 22: Functional Tests

- Module 23: Measured Values

- Module 24: Power Quality

- Module 25: Supervision

- Module 26: Communication

- Module 27: IEC 61850

- Module 28: Digital Twin

- Module 29: Case Study 7UT8

- Module 30: Case Study 7VK8

- Module 31: Case Study 7SA8

- Module 32: Case Study 7SS8

Course Details (Note: This part is continuously updating)

Module: SIPROTEC 5 Hardware and order

- SIPROTEC5 Hardware

- DIGSI 5 installation and DDD

- General Settings

- DIGSI 5 User interface

- New project + Add device (Offline)

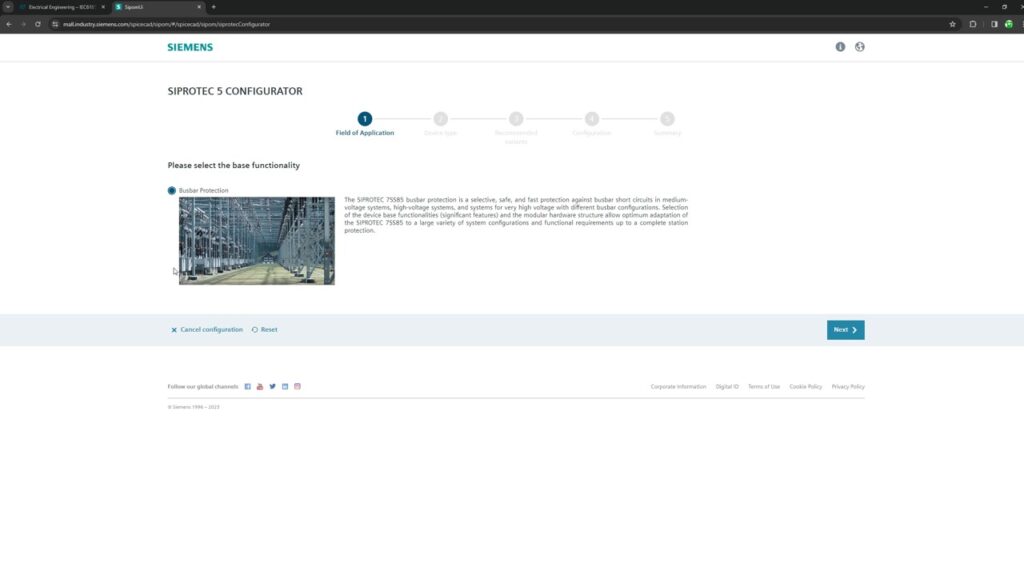

- Modify the order code in the SIPROTEC online configurator

- SIPROTEC 5 Online Configurator

- Function Point

- SIP 5 Configuration Procedure

Module: Online & Working with SIPROTEC 5

- Connect to SIPROTEC 5

- Indications

- Fault Recording

- Log

- Reading Indications on the On-Site Operation Panel

- Reading Indications from the PC with DIGSI 5

- Displaying Indications

- Operational Log

- Fault Log

- Switching-Device Log

- Ground-Fault Log

- Setting-History Log

- User Log

- Security Log

- Device-Diagnosis Log

- Communication Log

- Communication-Supervision Log

- Motor-Starting Log

- Saving and Deleting the Logs

- Spontaneous Indication Display in DIGSI 5

- Spontaneous Fault Display on the On-Site Operation Panel

- Stored Indications in the SIPROTEC 5 Device

- Resetting Stored Indications of the Function Group

- Test Mode and Influence of Indications on Substation Automation Technology

- Changing the Transformation Ratios of the Transformer on the Device

Module: System Functions

- Sampling-Frequency Tracking and Frequency Tracking Groups

- Text Structure and Reference Number for Settings and Indications

- Processing Quality Attributes

- Protection Communication

- Date and Time Synchronization

- User-Defined Objects

- Device Settings

- Data Types

- Function Control

- Connection Examples

- Chatter blocking

- Settings-Group Switching

Module: Function Groups

- Voltage current 3-Phase

- Circuit-breaker

- Process Monitor

- Voltage-current 1-phase

- Motor

- Line

- Voltage 3-Phase

- Analog Units

- User-Defined Function Group

- Recording

- Motor Monitor

- Current-Flow Criterion

- Circuit-Breaker Condition for the Motor

- Closure Detection

- Motor-State Detection

- Cold-Load Pickup Detection

- Thermal Replica Rotor

- Capacitor Bank

Module: Functions and Settings

- Power-System Data

- Overcurrent Protection, Phases

- Overcurrent Protection, Ground

- Line Differential Protection

- Stub Differential Protection

- Restricted Ground-Fault Protection

- Distance Protection with Reactance Method (RMD)

- Distance Protection with Classic Method

- Impedance Protection

- Power-Swing Blocking

- Teleprotection with Distance Protection

- Universal Teleprotection with Distance Protection

- Ground-Fault Protection for High-Resistance Ground Faults in Grounded Systems

- Teleprotection with Ground-Fault Protection

- Universal Teleprotection with Ground-Fault Protection

- Echo and Tripping in the Event of Weak Infeed 874

- Tripping with Missing or Weak Infeed According to French Specification

- External Trip Initiation

- Automatic Reclosing Function

- Directional Overcurrent Protection, Phases

- Positive-Sequence Overcurrent Protection

- Instantaneous High-Current Tripping

- Group Indications of Overcurrent Protection Functions

- Overcurrent Protection, 1-Phase

- Voltage-Dependent Overcurrent Protection, Phases

- Sensitive Ground-Fault Detection

- Non-Directional Intermittent Ground-Fault Protection

- Directional Intermittent Ground-Fault Protection

- Negative-Sequence Protection

- Directional Negative-Sequence Protection with Current-Independent Time Delay

- Undercurrent Protection

- Overvoltage Protection with 3-Phase Voltage

- Overvoltage Protection with Positive-Sequence Voltage

- Overvoltage Protection with Negative-Sequence Voltage

- Overvoltage Protection with Positive-Sequence Voltage and Compounding

- Overvoltage Protection with Zero-Sequence Voltage/Residual Voltage

- Overvoltage Protection with Any Voltage

- Undervoltage Protection with 3-Phase Voltage

- Undervoltage Protection with Positive-Sequence Voltage

- Undervoltage Protection with Any Voltage

- Rate-of-Voltage-Change Protection

- Undervoltage-Controlled Reactive-Power Protection

- Voltage-Comparison Supervision

- Fault Locator

- Fault Locator Plus

- Over frequency Protection

- Under frequency Protection

- Rate of Frequency Change Protection